Fluorescence Spectroscopy vs. Other Adulteration Detection Methods

Fluorescence spectroscopy is emerging as a fast, precise, and cost-effective method for detecting olive oil adulteration. Unlike chromatography and NMR spectroscopy, it requires minimal preparation, is non-destructive, and delivers results in minutes. By analyzing the natural light-emission patterns of olive oil compounds, it can detect even small amounts of contamination. While chromatography excels in detailed chemical profiling and NMR provides advanced molecular insights, both are slower, more expensive, and demand specialized skills. For producers needing quick, reliable quality checks, fluorescence spectroscopy offers a practical solution that balances accuracy and efficiency.

Quick Comparison

| Factor | Fluorescence Spectroscopy | Chromatography (GC/HPLC) | NMR Spectroscopy |

|---|---|---|---|

| Speed | Minutes | Hours | Moderate to slow |

| Preparation | Minimal | Extensive | Minimal |

| Cost per Test | Low | High | Moderate to high |

| Sample Destruction | No | Yes | No |

| Sensitivity | High (99.9%) | Very high | Moderate |

| Equipment Cost | Moderate | High | Very high |

| Operator Skill | Moderate | High | High |

Fluorescence spectroscopy stands out for its speed, ease of use, and affordability, making it an excellent choice for routine testing. Chromatography and NMR remain essential for detailed analysis and regulatory compliance, but their complexity and cost can limit their practicality for smaller operations.

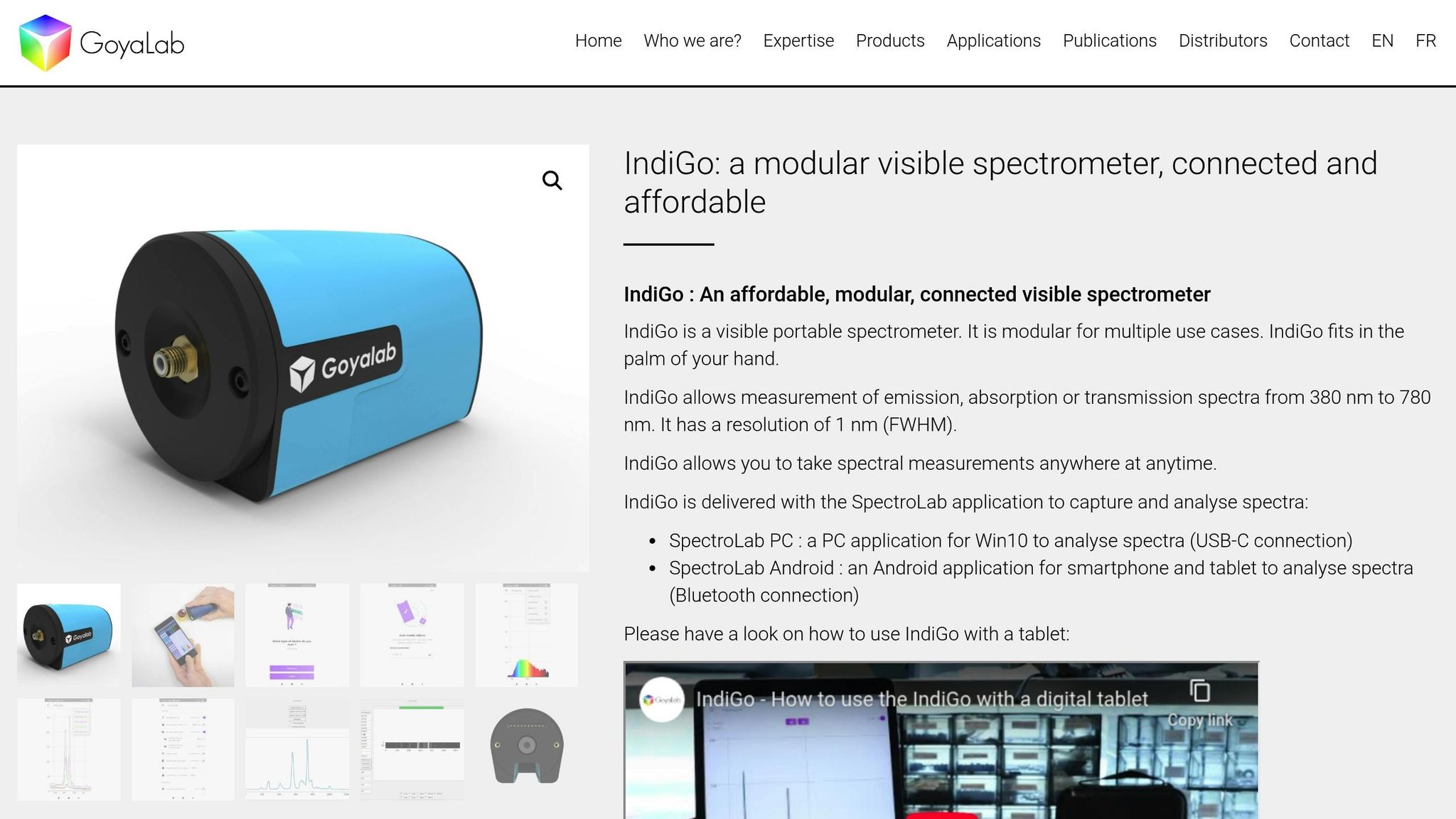

IndiGo Compact Spectrometer: Chemical Module

Common Detection Methods Overview

Detecting olive oil adulteration relies on a variety of advanced techniques, each offering a distinct way to uncover tampering. These approaches range from traditional lab-based methods to cutting-edge spectroscopic and chromatographic technologies capable of identifying even subtle alterations in olive oil's makeup.

Understanding these methods is key to knowing why certain techniques are better suited for specific adulteration scenarios. They play a crucial role in maintaining the quality and authenticity that premium producers, like those offering ultra-premium EVOO, depend on. The choice of method often hinges on factors such as the type of adulterants involved, the level of sensitivity required, and the resources available for testing. Reliable detection methods are essential for upholding trust in premium olive oil products. Below, we explore how fluorescence spectroscopy, chromatography, and NMR spectroscopy address the challenges of adulteration.

Fluorescence Spectroscopy

Fluorescence spectroscopy works by exposing olive oil samples to specific wavelengths of light. When the oil absorbs this energy, its natural compounds emit light at different wavelengths, creating a unique fluorescence "fingerprint" that reflects its composition.

Authentic extra virgin olive oil contains fluorescent compounds like chlorophyll derivatives, tocopherols, and phenolic compounds, which produce distinct emission patterns. If the oil has been mixed with lower-quality or foreign oils, these patterns can change in measurable ways. This method stands out for its sensitivity, as it can detect adulteration even when the amount of foreign oil is minimal. Recent innovations have also introduced portable devices for on-site testing, while lab-grade equipment continues to provide highly detailed analyses.

Chromatography Methods

Chromatography takes a different approach by separating the oil's components to identify markers of adulteration. This method breaks down the complex mixture of compounds in olive oil, allowing for detailed analysis of its individual elements. Two widely used techniques are Gas Chromatography-Mass Spectrometry (GC-MS) and High-Performance Liquid Chromatography (HPLC), each focusing on different types of molecules.

GC-MS is particularly effective for examining fatty acid profiles and volatile compounds. When adulterants are present, shifts in these characteristics become apparent. Authentic extra virgin olive oil has a specific fatty acid composition, and the introduction of foreign oils alters this profile in detectable ways.

HPLC, on the other hand, targets non-volatile components such as antioxidants, phenolic compounds, and pigments. This makes it especially useful for identifying contamination from refined oils, as the refining process often reduces these valuable compounds. While both GC-MS and HPLC provide detailed insights into adulteration, they require significant preparation time and specialized equipment.

Nuclear Magnetic Resonance (NMR) Spectroscopy

NMR spectroscopy offers a comprehensive view of olive oil’s molecular structure. This method involves placing a sample in a strong magnetic field and applying radiofrequency pulses to observe how atomic nuclei respond. The result is a detailed spectrum that reveals the oil's molecular composition without the need for chemical pretreatment.

Each type of oil has a unique NMR signature, making it possible to detect adulteration even in complex mixtures involving blended oils. Variations in the NMR spectrum clearly indicate discrepancies between authentic extra virgin olive oil and adulterated samples.

One of NMR spectroscopy’s greatest strengths is its ability to deliver extensive compositional data with exceptional reproducibility, making it a valuable tool for quality control and regulatory compliance. However, the method requires significant investment in advanced equipment and skilled personnel, which may limit its use for routine testing.

Fluorescence Spectroscopy for Olive Oil Testing

Let’s dive deeper into how fluorescence spectroscopy plays a key role in testing olive oil quality and authenticity.

How Fluorescence Spectroscopy Works

Fluorescence spectroscopy takes advantage of the natural fluorescent compounds found in olive oil. When these compounds are exposed to UV or visible light, they emit light at specific wavelengths. During testing, a light source excites the sample, and the emitted light is measured. These emission patterns are then compared to known authentic profiles, helping to identify any signs of adulteration. This precise technique is a cornerstone of modern olive oil analysis.

Benefits of Fluorescence Spectroscopy

This approach offers several practical benefits:

- Fast and sensitive testing: Results are obtained quickly, even with small sample sizes.

- Non-destructive analysis: Since the process doesn’t alter the sample, it can be reused for additional tests if needed.

- Cost-effective quality control: Its efficiency and reliability make it an excellent choice for routine quality checks.

Recent Advances in Fluorescence Spectroscopy

Recent developments in instrumentation and data processing have made fluorescence spectroscopy even more accessible and reliable. Enhanced consistency and user-friendly designs have strengthened its role in ensuring high-quality olive oil production.

sbb-itb-4066b8e

Method Comparison Analysis

Each detection method comes with its own set of strengths and trade-offs, shaping how quality control decisions are made.

Detection Methods Comparison Table

| Factor | Fluorescence Spectroscopy | Chromatography (GC/HPLC) | NMR Spectroscopy |

|---|---|---|---|

| Analysis Speed | Rapid (minutes) | Time-consuming (hours) | Moderate to slow |

| Sample Preparation | Minimal | Extensive | Minimal |

| Cost per Test | Low | High | Moderate to high |

| Sample Destruction | Non-destructive | Destructive | Non-destructive |

| Sensitivity | High (99.9% correlation) | Very high | Moderate |

| Regulatory Status | Emerging | Official methods | SNIF-NMR official |

| Equipment Cost | Moderate | High | Very high |

| Solvent Usage | None | Toxic solvents required | None |

| Operator Skill | Moderate | High | High |

The table provides an overview of the key distinctions, which are discussed in detail below.

Method Strengths and Limitations

Fluorescence spectroscopy shines in routine quality control thanks to its speed and simplicity. With a correlation coefficient of 0.999 for predicting adulterant levels, it’s both accurate and efficient. Its non-destructive nature and minimal sample preparation make it a cost-effective choice. Additionally, it reliably predicts critical quality indicators like free acidity and the K232/K270 indices, which align with International Olive Council standards.

Chromatography, on the other hand, is the go-to method for precise compositional analysis and detailed chemical profiling. This makes it indispensable for definitive authentication. However, its reliance on toxic solvents and destructive testing can complicate operations, especially for producers handling large volumes. These factors often slow down decision-making processes.

NMR spectroscopy offers a powerful tool for analyzing chemical composition and structure. With SNIF-NMR officially recognized for determining geographical and chemical origins, it provides reliable results for regulatory needs. Its non-destructive testing preserves samples for further analysis, but the high cost of equipment and moderate sensitivity for detecting low concentrations can pose limitations for widespread use.

For premium producers like Big Horn Olive Oil, choosing the right detection method depends on specific quality control requirements. Fluorescence spectroscopy is ideal for rapid screening, achieving 99.8% accuracy in distinguishing pure extra virgin olive oils from adulterated samples. Chromatography, despite its complexity, remains essential for final certifications and meeting regulatory standards. These comparisons highlight the growing need for faster, non-destructive methods, pushing regulatory bodies to reevaluate traditional practices.

Practical Considerations for Premium Producers

For premium olive oil producers like Big Horn Olive Oil, choosing the right detection method involves finding a balance between ensuring quality and maintaining operational efficiency.

Regulatory and Industry Standards

In the United States, olive oil producers face strict testing regulations. Traditional chromatographic methods, such as gas chromatography (GC) and high-performance liquid chromatography (HPLC), remain the go-to options for official certifications. Meanwhile, fluorescence spectroscopy is gaining attention as a promising alternative. Nuclear Magnetic Resonance (NMR), specifically SNIF‐NMR certification, also plays a critical role in verifying both the geographical origin and chemical authenticity of olive oil. This is particularly valuable for premium producers focused on sourcing oils from specific regions.

For smaller producers, meeting these stringent standards without compromising efficiency can be challenging. Fluorescence spectroscopy shows potential as a quick screening tool for detecting adulteration. However, when it comes to final certifications, more established chromatographic methods are still the norm. These regulatory requirements significantly influence both costs and operational decisions.

Scalability and Cost Analysis

For premium producers, the cost of testing methods must align with their commitment to product quality. This is especially important for smaller-scale operations. Fluorescence spectroscopy stands out as a cost-effective option, described by researchers as a "rapid and low-cost method" for identifying vegetable oil adulteration.

In contrast, traditional chromatographic methods come with higher expenses due to costly equipment, solvents, and maintenance. NMR spectroscopy, while requiring a larger initial investment, offers lower costs per analysis over time. Its minimal use of reagents and reduced sample preparation make it an efficient choice for producers conducting frequent tests. However, the upfront expense can be a barrier for smaller operations.

Operational efficiency is another key factor. For example, Big Horn Olive Oil, which prides itself on cold-pressing fresh harvest oils within two hours, benefits from testing methods that deliver fast results and integrate seamlessly into their time-sensitive workflows.

Impact and Resource Considerations

Beyond financial costs, resource allocation and environmental impact also influence the choice of testing methods. Fluorescence spectroscopy aligns well with sustainability-focused production. Researchers highlight its solvent-free, rapid, and cost-efficient nature, which benefits both producers and consumers.

For brands emphasizing natural processes, traditional chromatographic methods - reliant on toxic solvents and generating chemical waste - may clash with their clean, natural image. Fluorescence spectroscopy, with its minimal sample preparation and quick results, supports high-throughput quality control while reducing environmental harm.

"Most of these instrumental techniques require harmful reagents or expensive equipment with large operational and maintenance costs. In this context, fluorescence spectrometry is a simpler and less costly alternative."

Another consideration is staff training. Fluorescence spectroscopy typically requires only moderate operator skills, making it accessible to existing quality control teams. By comparison, chromatographic and NMR methods often demand specialized expertise and additional training, adding to operational complexity.

Finally, while advanced techniques like flash gas chromatography electronic nose systems offer cutting-edge capabilities, their high equipment costs have limited widespread adoption. For premium producers seeking advanced yet practical solutions, fluorescence spectroscopy’s moderate equipment costs make it an attractive option.

Choosing the Right Detection Method

Picking the best method to detect adulteration boils down to your specific needs, budget, and the quality standards you aim to uphold. For producers of premium olive oil, this decision is especially important - it directly affects the product's integrity and the trust consumers place in the brand. That’s where fluorescence spectroscopy stands out as a practical and efficient option.

This technique delivers quick and dependable results with impressive sensitivity, capable of detecting adulteration levels as low as 5%. Plus, it does so without compromising the sample, which helps reduce the use of costly consumables. By streamlining the quality control process, it ensures the oil’s freshness is preserved - perfect for operations where time is of the essence.

Another advantage of fluorescence spectroscopy is its ease of use. Unlike more complex methods like NMR or advanced chromatographic techniques, it requires only moderate operator skill. The equipment costs are reasonable, and ongoing maintenance expenses are minimal, making it a smart choice for producers striving to maintain high-quality standards.

For those managing fresh harvests, the minimal sample preparation required by this method supports fast-paced operations while still delivering accurate results. Its blend of speed and precision is especially beneficial for brands that prioritize rapid processing and rigorous quality assurance.

FAQs

What makes fluorescence spectroscopy different from chromatography and NMR for detecting olive oil adulteration?

Fluorescence spectroscopy offers a quick and non-invasive way to detect olive oil adulteration, capable of spotting contamination levels as low as 5%. This makes it a great choice for rapid preliminary screening.

In contrast, methods like HPLC and GC take more time but excel at separating and identifying individual components, making them ideal for confirmatory tests. Similarly, NMR delivers detailed chemical profiles with high accuracy but involves costly equipment and longer processing times, making it better suited for thorough verification.

Fluorescence spectroscopy shines for fast initial checks, while chromatography and NMR are more appropriate for detailed analysis and validation.

What makes fluorescence spectroscopy an effective method for detecting olive oil adulteration?

Fluorescence spectroscopy is a powerful method for spotting adulteration in olive oil. Its ability to detect even the smallest traces of impurities ensures an accurate evaluation of quality.

This technique is also fast, requiring little to no extensive sample preparation, and works with small sample sizes, making it efficient and budget-friendly. Beyond detecting impurities, it offers insights into the freshness and quality of olive oil, making it an essential tool for maintaining product standards and consumer confidence.

How can fluorescence spectroscopy help olive oil producers with on-site quality testing?

Fluorescence spectroscopy offers an efficient and reliable way to test olive oil right on-site. It’s a quick, non-invasive method that delivers precise results, making it ideal for identifying adulteration and evaluating quality. What’s great is that it eliminates the need for complicated lab setups, allowing producers to assess their oil’s purity and freshness with ease.

For olive oil producers, this translates to quicker decisions, stronger safeguards against fraud, and improved quality checks at production or storage locations. By ensuring their products meet high standards, producers can uphold their reputation and strengthen customer trust.