Gas vs. Liquid Chromatography in Adulteration Testing

Gas Chromatography (GC) and Liquid Chromatography (LC) are two advanced methods used to identify fraud in olive oil, an industry vulnerable to adulteration. GC focuses on volatile compounds like fatty acids and sterols, while LC examines non-volatile components such as triacylglycerols (TAGs) and phenolics. Each method has strengths and limitations, making them complementary tools for ensuring olive oil purity.

Key Takeaways:

- GC: Ideal for volatile compounds; detects seed oil contamination and subtle fraud like soft-deodorization. Requires complex preparation but offers high sensitivity.

- LC: Analyzes non-volatile molecules; efficient for TAG profiling and detecting refined oils. Faster and simpler preparation but involves higher costs for advanced systems.

Both methods are essential for combating fraud and verifying quality, especially for premium olive oil producers. Combining GC and LC provides a robust approach to detecting adulteration and maintaining industry standards.

Gas Chromatography (GC) Explained

How GC Works

Gas chromatography is a technique used to separate compounds that can be vaporized. Here's how it works: a sample is injected into an inert carrier gas - commonly helium or nitrogen - which moves the sample through a coiled column lined with a stationary phase. As the compounds travel, they interact with the column differently based on their volatility. More volatile molecules pass through faster, while less volatile ones take longer. This process is key for identifying adulterants in olive oil. At the column's end, the separated compounds are detected using tools like the Flame Ionization Detector (FID) or, for more detailed insights, Mass Spectrometry (MS). When paired as GC–MS, this combination is often considered the gold standard for analyzing volatile components in oils. This precise separation makes GC an essential tool for verifying olive oil authenticity.

Using GC for Olive Oil Testing

Gas chromatography is especially useful for spotting seed oil contamination through a process called Fatty Acid Methyl Ester (FAME) analysis. This involves converting fatty acids into FAMEs through saponification and methylation, revealing profiles that distinguish olive oil from cheaper seed oils. For example, in September 2017, researchers David C. Kennedy and Allen Misa from Phenomenex demonstrated that a modern column could cut analysis time from 60 minutes to just 20 while still meeting protocol standards.

Beyond fatty acids, GC can detect specific chemical markers that indicate adulteration. Brassicasterol suggests canola oil contamination, filbertone can reveal hazelnut oil, and high levels of trans-fatty acids may signal the use of refined or pomace oils. Using GC–FID, even small amounts - less than 5% - of sunflower oil adulteration can be detected.

GC also excels at uncovering more subtle fraud, such as soft-deodorization. This process involves treating oils at lower temperatures (around 212°F) to eliminate off-flavors. By analyzing the oil's aroma fingerprint through headspace analysis, GC can detect this type of manipulation.

"The term soft-deodorization refers to a deodorization process performed at a lower temperature... It basically consists of a vacuum steam distillation using nitrogen to strip out all the volatile compounds responsible for the undesirable odours" - Michele Suman, Food Safety and Authenticity Research Manager at Barilla Spa

This method is especially valuable for identifying manipulated oils that traditional bulk-fraction techniques might overlook.

GC Advantages and Drawbacks

Gas chromatography offers several clear benefits but also comes with some challenges. On the plus side, it provides exceptional sensitivity and consistency, allowing it to detect adulterants even at very low concentrations. This makes it a powerful tool for combating fraud. However, the technique has its limitations. Non-volatile compounds must undergo derivatization before they can be analyzed, which adds time and complexity to the preparation process. Additionally, GC is specifically designed for volatile substances, meaning it cannot directly analyze the roughly 90% of olive oil made up of triacylglycerols without converting them first. While traditional methods using 100-meter columns often require lengthy run times of about 60 minutes, newer targeted selectivity columns have significantly shortened this process.

Liquid Chromatography (LC) Explained

How LC Works

Liquid Chromatography (LC) is a technique designed to separate compounds within a liquid mobile phase, making it ideal for analyzing non-volatile or heat-sensitive molecules without needing to convert them. The process begins with injecting a dissolved sample into a solvent stream that flows through a packed column. Inside the column, compounds interact with the stationary phase at different rates, leading to their separation. Detectors like Charged Aerosol Detection (CAD) or Mass Spectrometry (MS) then identify the individual compounds. This method is particularly useful for analyzing triacylglycerols (TAGs) and sterols - key components that make up about 90% of olive oil. Unlike gas chromatography, which operates at high temperatures (up to 350°C), LC runs at ambient or controlled low temperatures, preserving delicate compounds that might degrade under intense heat. This makes LC a powerful tool for detecting adulteration markers in olive oil.

Using LC for Olive Oil Testing

LC provides a precise way to profile TAG compositions, as each type of oil has a unique TAG "fingerprint", making it a reliable method for authentication. Ultra-High-Performance Liquid Chromatography (UHPLC) paired with CAD allows for quick screening with minimal sample preparation - just simple dissolution. For instance, a study conducted in January 2020 demonstrated that UHPLC-CAD could analyze TAG profiles in various oils and blends within an hour. By applying Principal Component Analysis (PCA) to the results, researchers successfully identified adulteration in extra virgin olive oil (EVOO) with cheaper seed oils, even at levels as low as 10%. This level of precision underscores the rigorous standards needed for high-quality olive oils.

LC also plays a critical role in uncovering more sophisticated fraud. For example, in September 2020, researchers led by Cavanna, D. used LC combined with High-Resolution Mass Spectrometry (HRMS) to detect 12 specific molecular markers that revealed the presence of soft-deodorized lampante oils blended into EVOO. Michele Suman, Food Safety and Authenticity Research Manager at Barilla Spa, elaborated on this issue:

"The term soft-deodorization refers to a deodorization process performed at a lower temperature... the resulting soft-refined olive oils (SROO) are best used to blend EVOO and create illicit mixtures no longer detectable by current methods."

By analyzing sterol profiles, such as β-sitosterol levels, alongside TAG fingerprints, LC can differentiate between genuine EVOO and blends containing refined olive oil, pomace oil, or seed oils like sunflower or soybean.

LC Advantages and Drawbacks

LC offers several benefits when it comes to analyzing olive oil. It efficiently examines the TAGs that make up the majority of olive oil without requiring the extensive sample preparation often needed for gas chromatography. Additionally, LC performs well in gradient separations, enhancing the resolution of TAG peaks and making it easier to distinguish between different oil types. Modern UHPLC methods are faster and consume less solvent, which adds to their convenience, though solvent use is still a consideration.

However, LC does come with challenges. Advanced systems, such as LC-MS, are costly to purchase and operate, and they require skilled technicians to manage them. Older HPLC methods use more solvent, and interpreting the data often involves complex statistical tools or chemometric analysis. Despite these hurdles, LC remains an indispensable technique for detecting advanced adulteration methods that might evade traditional testing approaches.

Chromatographic Techniques for the Detection and Identification of Olive Oil Adulteration

sbb-itb-4066b8e

GC vs. LC: Direct Comparison

Gas Chromatography vs Liquid Chromatography for Olive Oil Testing Comparison

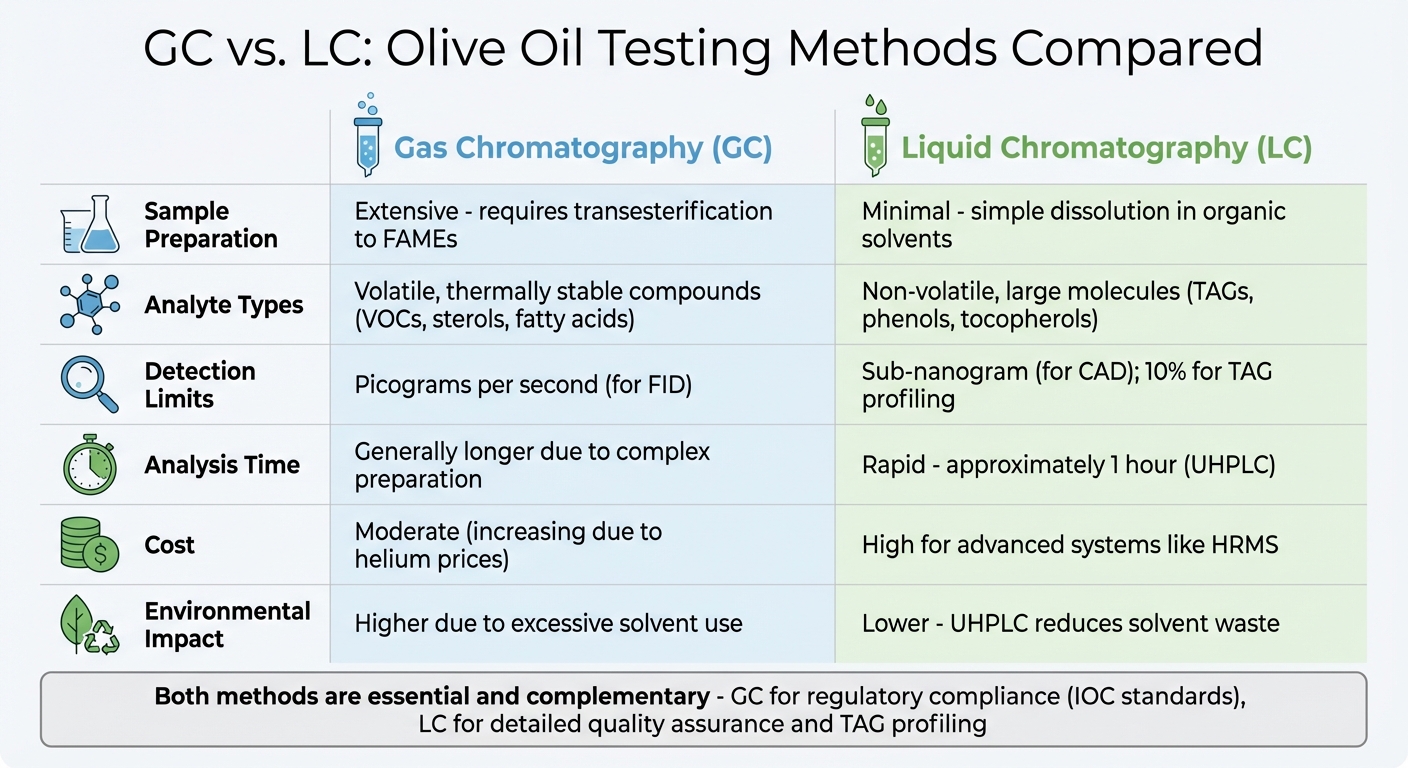

Now that we’ve explored the individual strengths of Gas Chromatography (GC) and Liquid Chromatography (LC), let’s see how they stack up side by side. These two methods take very different approaches when it comes to testing for olive oil adulteration. GC operates at high temperatures - reaching up to 662°F (350°C) - which makes it perfect for analyzing volatile compounds like fatty acids and sterols. On the other hand, LC works at ambient or cooler temperatures, making it better suited for heat-sensitive molecules such as triacylglycerols (TAGs), which form the bulk - around 90% - of edible oils.

The preparation requirements for each method also vary significantly. GC demands more extensive work, including a process called transesterification, which converts oils into fatty acid methyl esters (FAMEs). This step adds complexity and time. LC, particularly when using advanced techniques like UHPLC-CAD, requires much less effort. As noted in Food Control Journal, “Compared to traditional methods, UHPLC-CAD with PCA involves minimal sample preparation combined with fast analysis, for a rapid determination of EVOO authenticity”.

Speed and environmental considerations further distinguish these methods. Traditional GC techniques for profiling fatty acids and sterols often consume large amounts of solvents and require longer analysis times. In contrast, UHPLC can complete its screening in about an hour while generating less waste. That said, advanced LC systems, such as LC-HRMS, can be expensive to operate. The table below outlines these differences in key areas.

Comparison Table

| Criterion | Gas Chromatography (GC) | Liquid Chromatography (LC/UHPLC) |

|---|---|---|

| Sample Preparation | Extensive; requires transesterification to FAMEs | Minimal; simple dissolution in organic solvents |

| Analyte Types | Volatile, thermally stable compounds (VOCs, sterols, fatty acids) | Non-volatile, large molecules (TAGs, phenols, tocopherols) |

| Detection Limits | Picograms per second (for FID) | Sub-nanogram (for CAD); 10% for TAG profiling |

| Analysis Time | Generally longer due to complex preparation | Rapid; approximately one hour (UHPLC) |

| Cost | Moderate; increasing due to helium prices | High for advanced systems like HRMS |

| Environmental Impact | Higher due to excessive solvent use | Lower; UHPLC reduces solvent waste |

Both GC and LC have become indispensable tools in olive oil testing. The International Olive Council (IOC) uses GC for analyzing fatty acids and sterols, while LC is the go-to method for quantifying TAGs. These methods complement each other, targeting different compounds to ensure the authenticity of olive oil.

Selecting the Right Testing Method

What to Consider

When choosing a testing strategy, it's essential to weigh the strengths and limitations of each method against your objectives and regulatory requirements. For instance, if your goal is to verify fatty acid or sterol profiles for compliance purposes, GC-FID is non-negotiable. This is particularly true for legal certification of extra virgin olive oil (EVOO), as mandated by the International Olive Council (IOC) and EU Regulation (EEC) No 2568/91, which require GC for official purity testing.

That said, meeting regulatory standards alone doesn’t address every type of fraud. For example, soft-deodorized oils - refined at relatively low temperatures near 212°F (100°C) - can bypass standard GC detection because their composition is only slightly altered. In such cases, advanced tools like LC-HRMS or GC-IMS are needed to detect markers that conventional profiling might miss. Michele Suman, Food Safety and Authenticity Research Manager at Barilla Spa, highlights the challenge:

"The term soft-deodorization refers to a deodorization process performed at a lower temperature... the resulting soft-refined olive oils (SROO) are best used to blend EVOO and create illicit mixtures no longer detectable by current methods."

For high-throughput environments, UHPLC-CAD offers a fast and efficient solution, detecting adulteration levels as low as 10% in under an hour with minimal sample preparation. If the focus is on seed oil adulterants - like soybean, sunflower, or canola - GC is particularly effective at identifying increased levels of trilinolein or tripalmitin. On the other hand, LC excels in analyzing triacylglycerols (TAGs), which account for about 90% of edible oils and provide a distinct chemical fingerprint for each oil type. These methods not only ensure compliance but also reinforce the integrity of premium products.

Maintaining Premium Product Quality

Accurate testing plays a crucial role in combating food fraud, which affects nearly 10% of all commercial foods and costs the industry billions annually. For brands like Big Horn Olive Oil, which specializes in Ultra Premium Extra Virgin Olive Oils sourced from high-quality olives, rigorous testing is essential to uphold authenticity and purity. Using GC for sterol and fatty acid profiling ensures compliance with IOC standards, while incorporating LC-MS for triacylglycerol and phenolic analysis provides deeper chemical insights without the time-consuming derivatization required by GC.

Cutting-edge techniques like UPC2-QTOF MS can detect adulteration levels as low as 0.5% (v/v), offering an additional layer of protection for premium products. This level of precision is critical, especially considering reports that up to 80% of Italian extra virgin olive oil may be fraudulent. By combining GC for regulatory compliance with LC for detailed quality assurance, producers can confidently verify the authenticity of their oils and maintain consumer trust.

Conclusion

Gas Chromatography (GC) and Liquid Chromatography (LC) work hand in hand to tackle the challenge of olive oil fraud. GC is highly effective at analyzing volatile aroma compounds, fatty acids, and sterols, making it a trusted method for verifying geographical origins and identifying adulteration with seed oils. Meanwhile, LC focuses on triacylglycerols and phenolics - two critical components that influence oil quality.

This combination is especially valuable when addressing advanced fraud tactics, such as the use of soft-deodorized oils processed at approximately 212°F (100°C), which can evade detection through traditional testing methods. By pairing GC for regulatory checks with LC's ability to create detailed chemical profiles, producers can achieve a higher level of detection accuracy. For premium brands like Big Horn Olive Oil, which prides itself on sourcing Ultra Premium Extra Virgin Olive Oils from top-tier olives, this dual-method approach ensures both authenticity and consumer trust. This is crucial in a market where studies suggest that up to 80% of Italian EVOO could be fraudulent.

Ultimately, neither GC nor LC alone can meet the demands of modern fraud detection. Together, they provide the precise molecular analysis needed to uphold the integrity of premium olive oils and safeguard the industry against sophisticated fraud schemes.

FAQs

What’s the difference between gas chromatography and liquid chromatography in testing olive oil for adulteration?

Gas chromatography (GC) and liquid chromatography (LC) are both essential techniques for identifying olive oil adulteration, but each has its strengths depending on the type of analysis required.

GC is particularly effective for examining volatile or thermally stable compounds, such as fatty acids. However, it often requires a preparation step to make these compounds suitable for testing. The method stands out for its precision and sensitivity, especially when it comes to pinpointing specific fatty acid markers that indicate adulteration.

In contrast, LC shines when it comes to analyzing non-volatile components, like triacylglycerols (TAGs). Unlike GC, LC typically doesn’t require additional preparation, making it an excellent choice for mapping out the complete triglyceride profile of olive oil to spot potential adulterants. However, LC can be more time-consuming and often demands advanced equipment to match the sensitivity levels of GC.

To sum it up, GC is ideal for quick, targeted analysis, while LC delivers a more detailed look at the oil’s overall composition. Both methods play a crucial role depending on the specific requirements of the testing process.

Why is it beneficial to use both gas and liquid chromatography for detecting olive oil adulteration?

When testing for olive oil adulteration, combining gas chromatography (GC) and liquid chromatography (LC) offers a well-rounded approach. GC works best for detecting volatile compounds, such as aroma elements and fatty acid methyl esters, which can point to specific adulterants. Meanwhile, LC is better suited for analyzing non-volatile components like triacylglycerols and other key oil constituents, providing a more detailed look at the oil's makeup.

Using both methods together enhances detection sensitivity and precision, making it easier to identify even the smallest signs of adulteration. This ensures the olive oil meets authenticity and quality standards.

How do gas and liquid chromatography help verify the authenticity of premium olive oils?

Gas chromatography (GC) and liquid chromatography (LC) play a crucial role in verifying the authenticity of premium olive oils, including Big Horn Olive Oil’s Ultra Premium Extra Virgin Olive Oils (EVOO). These methods focus on different components of the oil to uncover potential adulteration.

GC is particularly adept at analyzing volatile compounds, such as aroma molecules and fatty-acid methyl esters. These compounds can indicate subtle alterations, like the blending of EVOO with refined or seed oils. By examining markers such as triglycerides and quality indices, GC effectively detects even low-level fraud.

LC, in contrast, examines non-volatile components like triacylglycerols (TAGs) and phenolic compounds. With advanced techniques, LC can generate detailed molecular profiles, making it easier to spot adulterated blends or oils sourced from different origins. When used together, GC and LC offer a thorough analysis, ensuring that every bottle of Big Horn Olive Oil upholds the highest standards of quality and authenticity.