How the Olive Council Ensures Product Authenticity

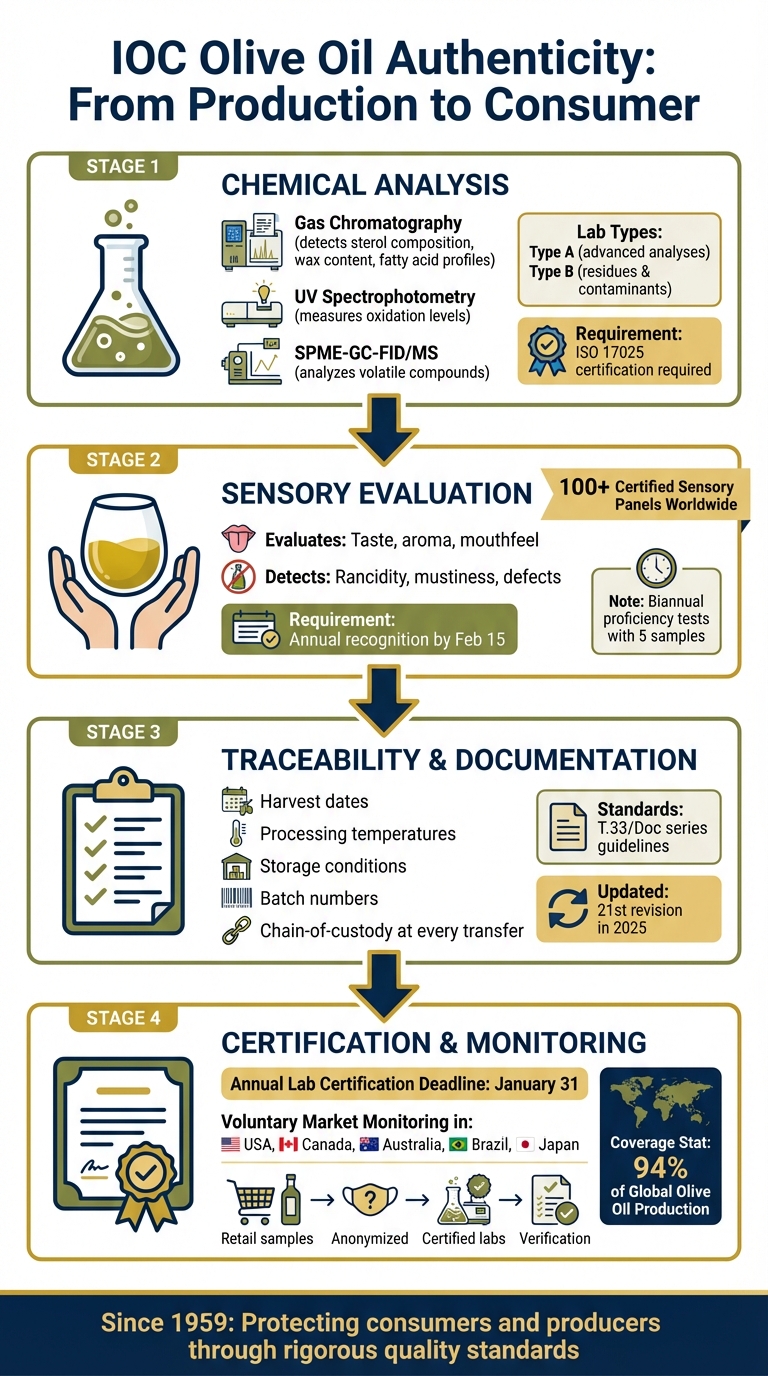

When you buy olive oil, you want to trust the label. The International Olive Council (IOC) makes this possible. Since 1959, they’ve set global standards to ensure what’s in the bottle matches what’s on the label. They use advanced chemical tests and trained tasters to detect fraud, like seed oil mixing or poor-quality refinement. Plus, they require detailed production records and traceability throughout the supply chain to maintain quality from harvest to shelf.

Key Points:

- Chemical Testing: Detects adulteration using methods like gas chromatography and UV spectrophotometry.

- Sensory Panels: Trained tasters ensure the oil meets flavor and aroma standards.

- Traceability: Strict documentation tracks the oil’s journey from production to purchase.

- Global Standards: The IOC’s rules apply across 94% of global olive oil production, ensuring consistency worldwide.

The IOC’s efforts protect both consumers and producers, ensuring every bottle labeled “extra virgin” meets strict quality benchmarks.

IOC Olive Oil Authentication Process: Chemical Testing to Consumer Protection

Methods for Verifying Olive Oil Authenticity

Since 1988, the International Olive Council (IOC) has relied on a combination of chemical analysis and sensory evaluation to verify the authenticity of olive oil. These methods assess both the oil's composition and its flavor and aroma profiles to ensure quality and detect fraud.

Chemical Analysis Techniques

Chemical testing plays a critical role in identifying adulteration, such as the illegal addition of seed oils to products marketed as extra virgin olive oil. To maintain accuracy, the IOC collaborates with a network of accredited laboratories, all of which must hold ISO 17025 certification and pass annual proficiency assessments.

Several advanced techniques are used in these analyses:

- Gas Chromatography: This method examines sterol composition, wax content, and fatty acid profiles to detect adulterants. For instance, the presence of stigmastadienes can reveal the addition of refined vegetable oils, while unusual triacylglycerol ratios may indicate seed oil contamination.

- UV Spectrophotometry: This technique measures oxidation levels to determine if the oil has been improperly refined.

- SPME-GC-FID/MS: Modern methods like solid-phase microextraction coupled with gas chromatography and mass spectrometry analyze volatile compounds, helping to confirm the oil's freshness and botanical origin.

Laboratories conducting these tests are classified into two categories: Type A labs handle advanced analyses, such as ethyl esters and phenolic compounds, while Type B labs focus on residues and contaminants. To stay ahead of evolving fraud tactics, expert chemists meet twice a year to update testing protocols.

While chemical analysis provides a detailed breakdown of the oil's composition, it’s only part of the equation. Sensory evaluation adds another layer of scrutiny by assessing characteristics that lab tests might miss.

Sensory Evaluation by Certified Panels

To complement chemical testing, sensory evaluation ensures that the oil's flavor profile aligns with extra virgin standards. The IOC recognizes over 100 certified sensory panels worldwide, each staffed by highly trained tasters. These panels evaluate taste, aroma, and mouthfeel to detect defects like rancidity or mustiness - issues that chemical tests might not fully capture.

"In 1981, driven by the aim of defining the organoleptic characteristics of virgin olive oils in precise, scientific terms, the IOC decided to develop a method for their evaluation." – International Olive Council

For consistency, sensory panels must apply for IOC recognition annually by February 15 and maintain ISO 17025 accreditation. The IOC also conducts biannual proficiency tests using five different samples to ensure uniform evaluation standards. This harmonized approach means a panel in Spain and one in California are likely to reach similar conclusions about an oil's quality. To minimize bias, the IOC provides standardized guidelines, including specific vocabulary, tasting glass requirements, and controlled test room conditions.

Traceability and Record-Keeping Requirements

Beyond laboratory testing, the International Olive Council (IOC) requires detailed documentation at every step of the production and distribution process. This ensures that extra virgin olive oil maintains its quality and authenticity from the olive harvest to the moment it reaches your kitchen.

Production and Harvest Records

Mills, refineries, and packing facilities must adhere to specific IOC guidelines, such as T.33/Doc. No 2-4, T.33-1/Doc. No 2-2, and T.33-2/Doc. No 4. These documents require meticulous record-keeping, including harvest dates, processing temperatures, storage conditions, and batch numbers. This creates a comprehensive history of each oil's production journey.

These records are crucial for verifying quality claims. For example, if a bottle of oil is labeled with a free acidity of 0.8 grams per 100 grams or less, the production records must substantiate this claim. To keep pace with advancements in fraud detection, the IOC updated its "Trade Standard Applying to Olive Oils and Olive-Pomace Oils" to its 21st revision in 2025.

This meticulous documentation ensures smooth chain-of-custody tracking throughout the supply chain.

Chain-of-Custody Documentation

Once the oil leaves the production facility, the IOC requires continuous tracking at every stage of the supply chain. Every transfer must be documented to confirm that the oil's classification remains consistent. The IOC's "Guide for Verifying the Conformity of a Previously Declared Commercial Category" (COI/GVCC/Doc. No 1/2020) outlines how to verify that the oil's category aligns with its original paperwork. For example, if a bulk shipment arrives at a packing plant labeled as extra virgin, the facility must confirm and document that the oil still meets those specifications before bottling.

Storage is another critical component of traceability. The IOC's "Best Practice Guidelines for the Storage of Olive Oils" (COI/BPS/Doc. No 1/2018) require facilities to monitor and document factors like temperature, light exposure, and humidity levels. These measures help prevent both accidental quality degradation and intentional tampering, ensuring that the oil consumers receive matches the quality certified by producers.

IOC Certification and Monitoring Programs

The International Olive Council (IOC) oversees the certification of laboratories and sensory panels across the globe. This ensures that all test results - whether chemical or sensory - adhere to strict, standardized criteria, no matter where the testing takes place.

Annual Certification of Testing Labs and Panels

Every year, the IOC recognizes chemical and sensory laboratories that meet its stringent requirements. To qualify, laboratories must hold ISO 17025 accreditation from a national accreditation body, which guarantees compliance with established quality standards.

Certified labs fall into two categories: advanced (Type A) and routine (Type B). Type A labs conduct specialized analyses, such as those for ethyl esters and phenolic compounds, while Type B labs focus on testing residues and contaminants. Applications for certification must be submitted directly to the IOC Executive Secretariat by January 31 each year.

Sensory panels face additional requirements. They are not permitted to apply directly to the IOC; instead, they must go through their national competent authority by February 15. These panels must also have government approval to oversee the official control of virgin olive oils. The IOC ensures the reliability of sensory panels by organizing proficiency tests twice a year. These evaluations involve five specific samples to verify consistency across more than 100 recognized panels worldwide. Additionally, the IOC hosts three-day workshops to harmonize sensory assessment methods among all panels.

Alongside these certifications, the IOC conducts voluntary market monitoring to further uphold product quality and authenticity.

Voluntary Market Monitoring Programs

To reinforce the integrity of olive oil products, the IOC also runs a voluntary market monitoring initiative. This program acts as a self-regulation system for import markets, where importers and distributors commit to adhering to IOC standards. According to the IOC:

"This is a voluntary programme that can be regarded as a self-regulation system in which importers and distributors commit themselves to respect IOC regulations".

Under this program, samples are collected directly from retail shelves in participating countries. The IOC anonymizes and re-labels these samples before sending them to certified laboratories for detailed analysis of chemical properties, sensory qualities, and labeling accuracy. Initially launched in the United States and Canada in July 1991, the program has since expanded to include Australia (January 1993), Brazil, and Japan. This independent verification ensures that the extra virgin olive oil consumers buy meets the claims stated on the label.

sbb-itb-4066b8e

IOC Standards and Ultra Premium Olive Oils

The International Olive Council (IOC) sets stringent benchmarks to define Ultra Premium Extra Virgin Olive Oil (EVOO), focusing on stricter criteria for freshness, purity, and chemical composition that go beyond the basic requirements for extra virgin olive oil. These rigorous standards guarantee that products, like those from Big Horn Olive Oil, consistently deliver top-tier quality. The IOC's "Trade Standard Applying to Olive Oils and Olive-Pomace Oils" (COI/T.15/NC No 3/Rev.21/2025) serves as the quality baseline, with advanced testing methods ensuring authenticity and identifying any adulteration with seed oils or olive-pomace oil. These protocols are key to maintaining the elevated standards required for Ultra Premium classification.

Ensuring Freshness and Purity

Freshness is assessed through specific chemical tests, including measurements of free fatty acids, peroxide value, and UV spectrophotometric readings. Ultra Premium EVOOs are distinguished by their minimal levels in these tests, signaling exceptional quality. Big Horn Olive Oil adheres to these principles by cold-pressing olives within two hours of harvest and ensuring delivery within three months. This rapid processing preserves peak freshness, retains high antioxidant levels, and enhances the bold flavor profiles that set Ultra Premium EVOO apart from standard varieties.

To further safeguard quality, the IOC provides detailed storage guidelines (COI/BPS/Doc. No 1) to help producers and distributors maintain the integrity of their oils from production to purchase. Proper storage conditions - such as protecting oils from heat, light, and air - prevent oxidation and degradation, ensuring the product remains at its best. These stringent measures are supported by robust traceability protocols, reinforcing trust and confidence among consumers.

Traceability and Consumer Confidence

The IOC's traceability framework (COI/GVCC/Doc. No 1) ensures transparency throughout the supply chain, allowing consumers to verify label claims and confirm the authenticity of Ultra Premium EVOO. Big Horn Olive Oil takes this a step further by sourcing from verified producers and meticulously documenting harvest dates, production methods, and chemical analysis results. This thorough record-keeping guarantees that every bottle matches the quality standards promised, building trust through verifiable data rather than relying solely on marketing claims.

Conclusion

The International Olive Council (IOC) plays a crucial role in safeguarding the integrity of olive oil products through rigorous chemical testing, certified sensory evaluations, and transparent traceability. By setting strict standards, the IOC ensures fairness in the market, protecting both producers and consumers from fraud and mislabeling. Their dual-testing system - combining advanced chemical analysis to detect adulteration with sensory evaluations conducted by over 100 recognized panels globally - ensures that products labeled as "Extra Virgin" meet stringent quality benchmarks. This comprehensive process helps maintain trust in every bottle, from harvest to the moment it reaches the consumer.

The IOC also works closely with international standardization bodies to eliminate ambiguity and ensure consumer protection. Through certification and voluntary monitoring programs, they guarantee that retail products align with their label claims.

Producers like Big Horn Olive Oil exemplify how these standards can be upheld. By adhering to IOC protocols, they ensure quality through meticulous record-keeping, verified sourcing, and rapid processing. Their commitment to delivering olive oil within three months of harvest and maintaining full supply chain transparency reflects the principles championed by the IOC.

These systems make quality both measurable and verifiable. Choosing Ultra Premium Extra Virgin Olive Oil that complies with IOC standards means you're not just buying olive oil - you’re investing in a product backed by decades of research and standardization. This dedication to excellence not only protects consumers but also enhances the global reputation of premium olive oil.

FAQs

How does the International Olive Council (IOC) ensure olive oil is free from seed oil adulteration?

The International Olive Council (IOC) employs sophisticated chemical analysis techniques to determine if olive oil has been adulterated with seed oils or other substances. Tools such as gas chromatography and liquid chromatography are used to detect even the smallest traces of seed oils or olive-pomace oil. Additionally, the oil's fatty acid composition and triacylglycerol (TAG) profiles are examined to verify it aligns with strict quality and authenticity benchmarks.

These detailed testing procedures are essential for preserving the integrity of olive oil, ensuring that consumers receive pure, high-quality products that adhere to international regulations.

How do sensory panels ensure the quality of olive oil?

Sensory panels play a key role in determining the quality of olive oil. Made up of trained tasters, these panels evaluate the oil's flavor, aroma, and identify any possible defects. By adhering to strict, standardized protocols, they assess whether the oil meets the rigorous standards required to earn the label of extra virgin.

This meticulous process ensures that only top-tier olive oils, such as Ultra Premium Extra Virgin Olive Oils, are acknowledged for their genuine quality. Sensory panels are vital in upholding the reputation and reliability of olive oil products.

How does the International Olive Council ensure the authenticity of olive oil products?

The International Olive Council (IOC) plays a key role in maintaining the integrity of olive oil by enforcing rigorous traceability and record-keeping protocols. These standards ensure that every step of the supply chain - starting from the olive grove and ending with the bottled product - is carefully documented and verified for both origin and quality.

Through these detailed checks and oversight, the IOC safeguards consumers from potential fraud while ensuring that the olive oil they buy aligns with global quality benchmarks. This dedication not only protects buyers but also reinforces trust and confidence in olive oil products on a worldwide scale.