Free Acidity in Olive Oil: Testing Methods Explained

Free acidity is a key factor in evaluating olive oil quality. It measures the percentage of free fatty acids, reflecting how well olives were handled from harvest to bottling. Extra virgin olive oil must have free acidity of 0.8% or less, per International Olive Council (IOC) standards, while virgin olive oil can go up to 2.0%. Lower acidity generally indicates better handling and storage, resulting in fresher oil with a longer shelf life.

Testing Methods for Free Acidity:

- Titration: Standard, lab-based method using alkaline solutions to measure acidity. Accurate but requires time and expertise.

- Digital Image Colorimetry: Uses a smartphone to analyze color changes, reducing chemical use and offering faster results.

- Voltammetric Analysis: Advanced technique for precise acidity measurement but requires specialized equipment and expertise.

- CDR OxiTester: Portable device providing quick results (1 minute) via photometric analysis, ideal for on-site testing.

Each method has trade-offs in speed, cost, and accuracy. Titration remains a benchmark for certification, while newer methods like the CDR OxiTester and colorimetry are practical for routine checks. For consumers, choosing certified low-acidity olive oil ensures better quality and flavor.

Interpreting Olive Oil Test Results

How Free Acidity Affects Olive Oil Grading

Free acidity plays a critical role in determining olive oil quality. According to International Olive Council (IOC) standards, oils are classified as extra virgin if their free acidity is 0.8% or less, and virgin if it is 2.0% or less. These limits reflect the oil's chemical purity and the meticulous handling of olives from harvest to bottling. Oils exceeding 2.0% free acidity are relegated to lower quality categories and often require refining before they are suitable for consumption.

International Olive Council Standards for Free Acidity

The IOC has established global standards to ensure a consistent measure of olive oil quality. When you pick up a bottle labeled "extra virgin", you can trust that it adheres to strict chemical benchmarks, regardless of where it was produced. The 0.8% acidity threshold ensures the oil comes from healthy, undamaged olives that were processed promptly and with care.

Free acidity testing is part of a broader quality evaluation that includes peroxide values, UV absorbance, and sensory assessments by professional taste panels. While an oil might pass the acidity test, it could still fail if sensory defects or off-flavors are detected. However, free acidity remains the primary indicator - any oil exceeding 0.8% acidity automatically loses its extra virgin status, no matter how good it tastes. This highlights the importance of swift harvesting and proper storage in maintaining oil quality.

How Harvesting and Storage Affect Free Acidity

The journey from olive to oil is a race against time. Fresh, healthy olives straight from the tree have 0% free acidity because their fats are naturally stable. The moment olives are picked, however, enzymes and microbes begin breaking down triglycerides into free fatty acids. To minimize this process, early harvesting of mature but undamaged olives and gentle mechanical picking methods are essential.

Studies show that damaged or overripe olives can experience a rapid spike in acidity - doubling within hours if not processed immediately. For instance, research comparing harvesting techniques found that late-picked or roughly handled olives could reach acidity levels of 1.5–3.0% after extraction. In contrast, early-harvest methods often keep acidity levels below 0.5%. Premium producers, such as Big Horn Olive Oil, select only the best 5% of olives for processing. Starting with top-quality fruit is key to achieving the ultra-low acidity levels that define exceptional extra virgin olive oil.

Storage conditions are just as important as harvesting. Even the best oils degrade over time. This is why Big Horn Olive Oil ships bottles within 1–3 months of harvest and advises consuming them within 9 months of the crush date, following recommendations from The UC Davis Olive Center. Proper storage - keeping oil in dark, cool conditions - can slow the breakdown of fats, but it cannot stop it entirely. Ultimately, freshness remains a crucial factor in preserving low free acidity throughout the oil's shelf life.

Testing Methods for Free Acidity

Measuring free acidity is a critical part of assessing the quality of olive oil, complementing both physical and sensory evaluations. This process requires specialized laboratory techniques, with titration being the standard method approved by the International Olive Council (IOC). In titration, a measured olive oil sample is dissolved in a neutralized solvent mixture - usually ethanol and ether - and titrated with a standardized sodium or potassium hydroxide solution. Phenolphthalein serves as the indicator, and a pale pink color that persists marks the endpoint. Each testing method comes with its own advantages, balancing factors like speed, chemical use, and precision.

Titration Method

Titration remains the "official" method for determining free acidity, and newer techniques are often calibrated against its results. Known for its high accuracy and reliability, titration expresses results as a percentage of free fatty acid. However, it’s not without challenges. Common errors can occur due to improper standardization of the alkaline solution, difficulty detecting the endpoint (especially with darker oils), incomplete sample dissolution, absorption of CO₂ by the titrant, and mistakes in reading the burette. Despite these potential pitfalls, titration continues to serve as the primary method for compliance and official grading.

Digital Image Colorimetry

Digital image colorimetry offers a modern alternative that significantly reduces chemical usage. In this method, the oil is mixed with a color-changing reagent, and the resulting color is captured using a smartphone. The intensity of the color correlates with the level of acidity. A dedicated app analyzes the image, extracts numerical color data, and translates it into free acidity values using pre-calibrated models. This approach uses about 90% fewer chemicals than traditional titration and provides results more quickly, all while maintaining accuracy when properly calibrated to the standard method.

Voltammetric Analysis

Voltammetric analysis is another advanced technique, utilizing a platinum microdisk electrode immersed in olive oil mixed with an ionic liquid electrolyte to enable conductivity. A controlled potential scan reduces free fatty acids, generating current profiles that are analyzed using multivariate calibration. This data, processed through a Partial Least Squares regression model, predicts acidity with a deviation of around 5%. Calibration relies on oil standards with acidity previously determined through titration, covering a range of 0.2–1.5% w/w for extra virgin olive oils. While accurate, this method requires specialized equipment, skilled operators, and careful maintenance of the microelectrodes, making it less practical for routine use in olive mills.

CDR OxiTester Photometric Analysis

The CDR OxiTester provides a fast and portable solution through a photometric assay. To test, a small amount of olive oil is added to a reagent-filled cuvette, mixed, and inserted into the analyzer, which measures absorbance at approximately 630 nm. The reduction in color intensity directly correlates with free acidity, delivering results in about one minute per sample. Designed to align with the official titration method, the CDR OxiTester offers reliable results and is particularly useful for on-site testing in mills or packaging facilities due to its ease of use and portability.

sbb-itb-4066b8e

Comparing Testing Methods

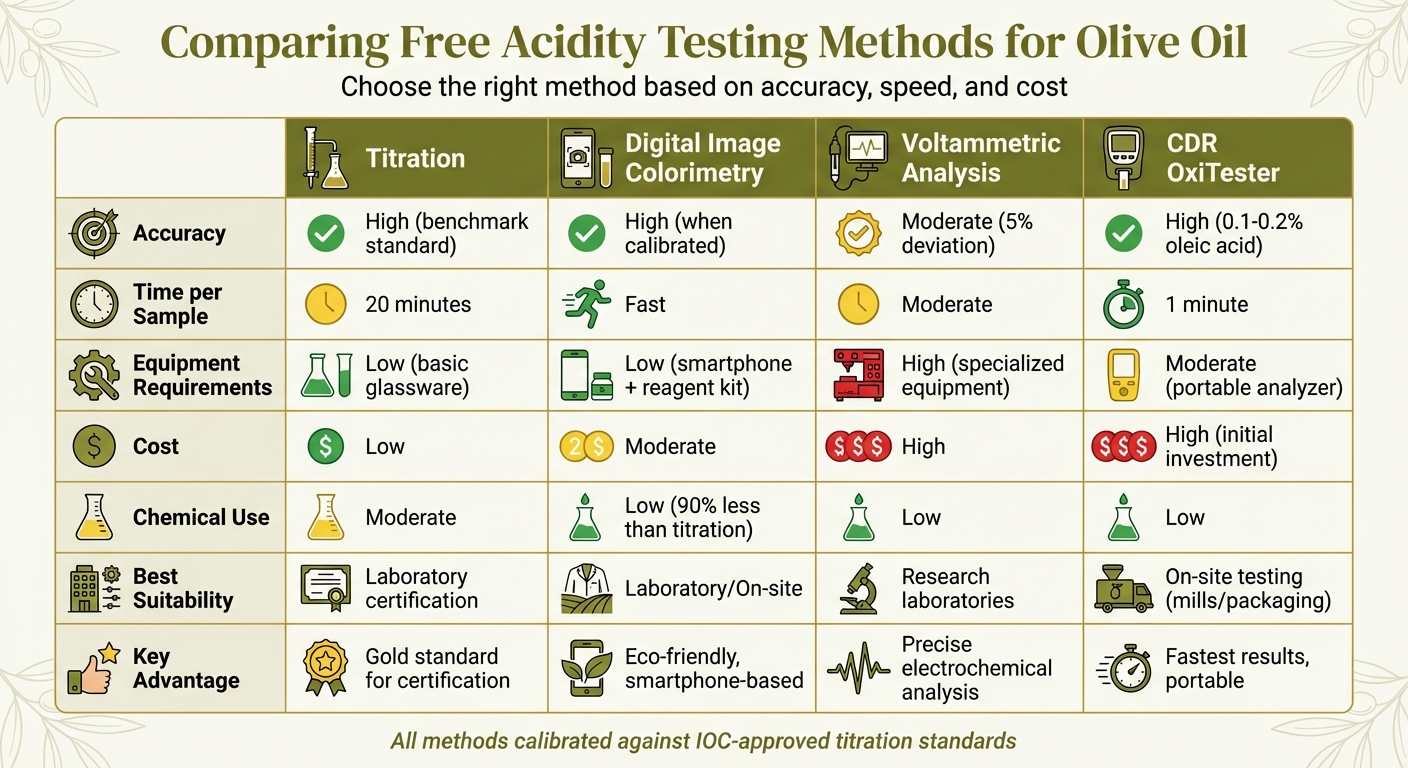

Olive Oil Free Acidity Testing Methods Comparison Chart

Advantages and Disadvantages of Each Method

Continuing from our earlier discussion of individual testing methods, let’s now weigh their practical trade-offs for both producers and quality certifiers.

Each method has its own strengths and challenges. Titration is often considered the benchmark due to its high accuracy and relatively low upfront costs - it only requires basic glassware and reagents. However, it takes around 20 minutes per sample and needs a trained operator in a lab environment. On the other hand, digital image colorimetry is much quicker, using about 90% fewer chemicals than titration. This method pairs a smartphone with a reagent kit, offering high accuracy at a moderate cost, though it depends on reliable calibration models.

Other methods cater to specific needs by balancing speed, cost, and accessibility. Voltammetric analysis delivers moderate accuracy, with deviations under 5% compared to titration for 0.2–1.5% acidity. However, it demands specialized equipment and skilled operators, driving up both equipment and operational costs. This makes it most suitable for research labs. Meanwhile, the CDR OxiTester stands out for its speed - producing results in just one minute - with high accuracy and repeatability (0.1–0.2% oleic acid). Its portability and user-friendly design make it perfect for on-site testing at mills and packaging facilities, though the initial investment in the analyzer is higher.

Here’s a quick comparison of these methods:

| Method | Accuracy | Time | Equipment | Cost | Chemical Use | Suitability |

|---|---|---|---|---|---|---|

| Titration | High | 20 mins | Low | Low | Moderate | Laboratory |

| Digital Image Colorimetry | High | Fast | Low | Moderate | Low | Laboratory/On-site |

| Voltammetry | Moderate | Moderate | High | High | Low | Laboratory |

| CDR OxiTester | High | 1 min | Moderate | High | Low | On-site |

For smaller producers looking for affordable options, titration or digital image colorimetry provide excellent value with minimal equipment requirements. Larger operations, such as mills or brands prioritizing quality, may lean toward the CDR OxiTester for its speed and convenience in batch testing, while still using titration periodically for certification. Ultimately, the choice of method depends on balancing certification needs, speed, environmental considerations, and budget.

Conclusion

Key Takeaways

Free acidity testing plays a vital role in determining olive oil quality, especially when classifying it as extra virgin (≤0.8% acidity). This benchmark ensures that olives were harvested fresh and handled properly throughout production.

Each testing method discussed has its own advantages in maintaining quality. Titration remains the global standard - cost-effective, reliable, and widely used, though it requires significant chemical reagents. Digital image colorimetry offers a cleaner, more sustainable approach, cutting chemical use by up to 90% and opening the door to smartphone-based testing outside traditional labs. Voltammetric analysis provides fast and highly sensitive results but demands specialized equipment and expertise. Meanwhile, the CDR OxiTester photometric method delivers results in about a minute with minimal preparation, making it perfect for quick decisions during production. While no single method fits every scenario, traditional titration is indispensable for certification, and newer, low-reagent techniques are ideal for routine checks.

For U.S. consumers, selecting certified low-acidity extra virgin olive oil ensures better flavor, longer shelf life, and the retention of health-promoting antioxidants and polyphenols. On the other hand, higher acidity may signal hydrolytic rancidity caused by poor storage or damaged olives - something to avoid when prioritizing quality. These quality measures reflect the dedication of premium producers to delivering exceptional products.

Big Horn Olive Oil's Commitment to Quality

Big Horn Olive Oil exemplifies a steadfast dedication to quality, adhering to rigorous testing standards to provide exceptional extra virgin olive oil. By leveraging reliable free acidity testing, they ensure their oils meet the highest benchmarks. The company sources only the top 5% of premium olives for production and ships bottles to customers within 1–3 months of harvest. Their ultra-premium oils not only surpass standard EVOO requirements but also boast high levels of antioxidant biophenols and smoke points of 410°F or more, underscoring their commitment to low free acidity and meticulous quality control. Whether part of their traditional or infused ranges, every bottle reflects careful sourcing and a deep understanding that quality starts at the grove and is maintained through every step of production.

FAQs

Why is digital image colorimetry considered better than traditional titration for testing free acidity in olive oil?

Digital image colorimetry stands out as the preferred method for testing free acidity in olive oil due to its speed and precision. This approach significantly reduces the chances of human error compared to traditional titration methods. Another advantage? It’s non-destructive, meaning the olive oil sample remains untouched and intact after testing. Plus, digital image colorimetry ensures consistent and objective results, making it a dependable option for maintaining olive oil quality and meeting strict certification requirements.

How does free acidity influence olive oil’s freshness and taste?

Free acidity plays an important role in determining the quality and freshness of olive oil. Oils with lower free acidity levels tend to be fresher and deliver a smoother, more enjoyable flavor. In contrast, higher free acidity can accelerate spoilage, resulting in a bitter or rancid taste. This not only affects the oil's flavor but also reduces its shelf life and overall quality.

Why does low free acidity matter in olive oil quality?

Low free acidity is one of the most telling signs of high-quality olive oil. It reflects proper processing and storage, meaning the oil has experienced minimal degradation. This not only preserves its taste but also extends its shelf life and retains its health-promoting properties.

Extra virgin olive oils, in particular, are celebrated for their low acidity levels. These oils keep their natural flavors intact and are packed with nutrients, making them a flavorful and healthier option for both cooking and everyday use.