NIR vs. Fluorescence: Spectroscopy for Olive Oil

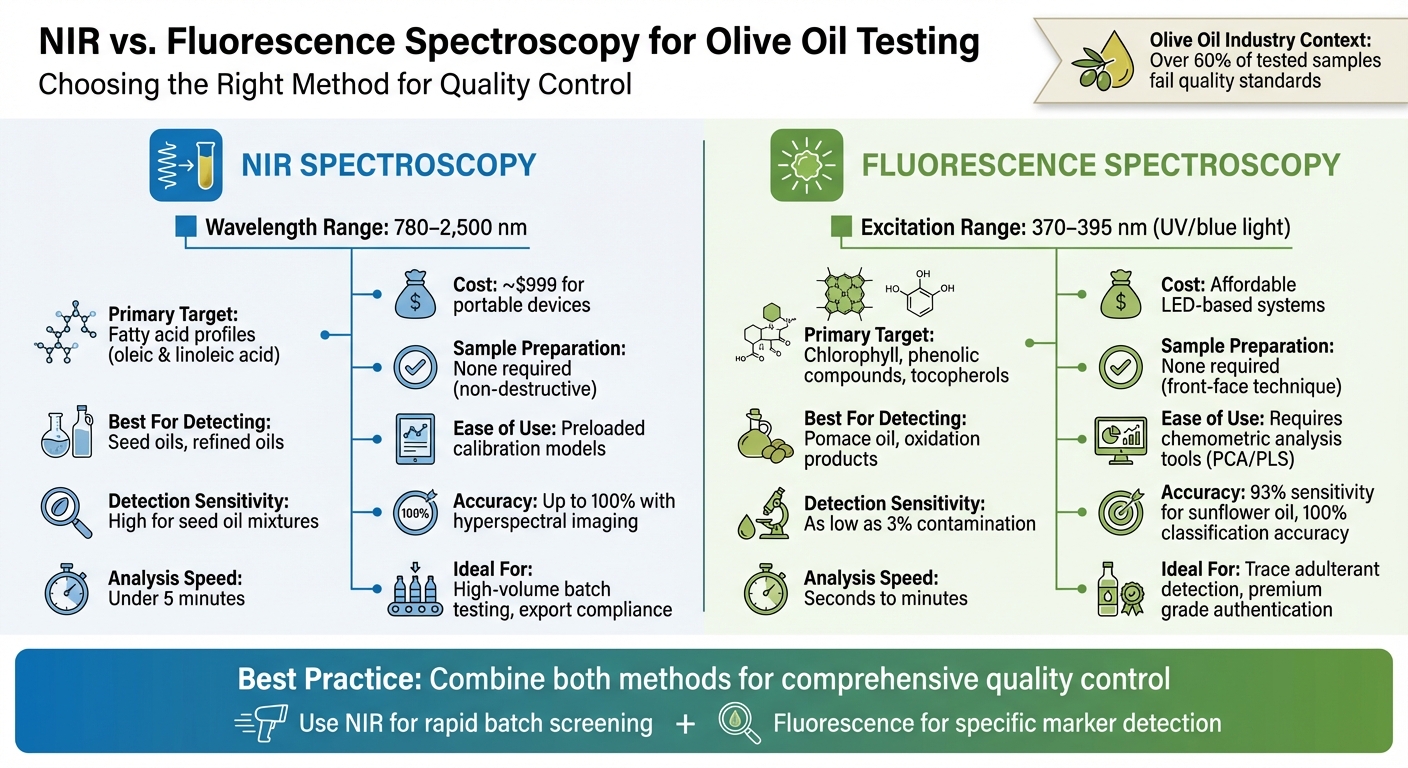

Fraud in extra virgin olive oil (EVOO) is a growing issue, with over 60% of tested samples failing to meet quality standards. Two advanced methods - Near-Infrared (NIR) and Fluorescence spectroscopy - offer fast, reliable ways to detect adulteration and ensure quality. Here's what you need to know:

- NIR Spectroscopy: Uses light (780–2,500 nm) to analyze fatty acid profiles, like oleic and linoleic acid, and identify adulterants such as seed oils. It's fast (under 5 minutes), non-destructive, and portable systems are available for ~$999.

- Fluorescence Spectroscopy: Excites molecules with UV or blue light to measure emitted wavelengths, detecting markers like chlorophyll and phenolic compounds. It can spot contaminants at concentrations as low as 3% and is cost-effective with LED-based devices.

Quick Comparison

| Feature | NIR Spectroscopy | Fluorescence Spectroscopy |

|---|---|---|

| Primary Target | Fatty acid profiles | Chlorophyll, phenolic compounds |

| Detection Sensitivity | High for seed oils | 3% for pomace oil |

| Speed | <5 minutes | Seconds to minutes |

| Cost | ~$999 for portable devices | Affordable LED-based systems |

| Ease of Use | Preloaded calibration models | Requires chemometric tools |

While NIR is ideal for quick batch testing, fluorescence excels in detecting specific markers. Combining both methods ensures thorough quality control for EVOO producers.

NIR vs Fluorescence Spectroscopy for Olive Oil Testing Comparison

Near-Infrared (NIR) Spectroscopy: How It Works

How NIR Spectroscopy Works

NIR spectroscopy operates by passing light in the 780–2,500 nm range through olive oil. As the light interacts with the oil, molecules absorb energy at specific wavelengths, depending on their chemical bonds - primarily C-H, O-H, and N-H bonds. This interaction creates a unique spectral fingerprint that reveals the oil's composition.

This method focuses on analyzing fatty acid profiles, particularly the balance between monounsaturated fatty acids (MUFA) like oleic acid and polyunsaturated fatty acids (PUFA) like linoleic acid. For example, authentic extra virgin olive oil (EVOO) typically contains about 76% oleic acid. In contrast, many seed oils used for adulteration are rich in linoleic acid. NIR can also identify minor compounds like sterols, polyphenols, vitamin E, and pigments such as chlorophyll and carotenoids - key markers of high-quality olive oil.

Given the complexity of NIR spectra, chemometric analysis is essential for interpreting the data. Techniques like Principal Component Analysis (PCA) help classify oil types and uncover patterns, while Partial Least Squares (PLS) regression quantifies the level of adulterants. These advanced analyses make NIR a powerful tool for evaluating olive oil quality and authenticity.

Benefits of NIR for Olive Oil Testing

NIR spectroscopy brings several advantages to olive oil testing. It’s a non-destructive method, meaning the oil sample remains intact, with no need for extensive preparation, harmful reagents, or specialized operators.

One standout feature is its ability to detect multiple adulterants at once. This includes common additives like sunflower, soybean, corn, sesame, flax, palm olein, and refined olive oils. When combined with hyperspectral imaging, NIR has demonstrated classification accuracies of up to 100% in distinguishing authentic EVOO from adulterated mixtures.

The rise of portable NIR systems has further increased accessibility. For instance, the Texas Instruments DLP NIRscan Nano module, priced around $999, uses Digital Light Processing (DLP) technology and advanced photodetectors like InGaAs to analyze specific wavelengths. In July 2022, researchers from the Istituto di Fisica Applicata "Nello Carrara" (IFAC-CNR) employed the SCiO pocket spectrometer with a 3D-printed holder to test 116 Italian olive oil samples. Their work achieved a 92% success rate in differentiating EVOO from non-EVOO.

"NIRS technology has many applications in the food industry sector; it is used to analyze food safety and quality parameters along the food chain." - Candela Melendreras et al., University of Oviedo

Drawbacks of NIR Technology

While NIR spectroscopy has impressive capabilities, it’s not without challenges. The equipment itself can be cost-prohibitive - benchtop systems typically range from $15,000 to $100,000. However, portable and secondhand options offer more budget-friendly alternatives.

Another hurdle is the complex calibration process. Accurate results depend on building robust models with extensive libraries of both pure and adulterated samples. These models must account for variations across olive varieties and harvest years. Without well-trained calibration sets and chemometric expertise, the reliability of the results could suffer.

Portable devices, while convenient, often have narrower spectral ranges (e.g., 900–1,700 nm) compared to their laboratory counterparts. This limitation may reduce their effectiveness in detecting certain components under specific conditions.

Fluorescence Spectroscopy: How It Works

How Fluorescence Spectroscopy Works

Fluorescence spectroscopy works by exciting molecules with UV or blue light and measuring the wavelengths they emit afterward. When olive oil is exposed to ultraviolet (UV) or blue light, typically in the 370–395 nm range, its natural fluorophores absorb this energy and release it at longer wavelengths, usually between 670–740 nm.

Key fluorophores in olive oil include chlorophyll (emitting at 670–690 nm), carotenoids, tocopherols (Vitamin E), and phenolic compounds. For instance, high-quality extra virgin olive oil (EVOO) with abundant chlorophyll shows a strong fluorescence peak at 670–675 nm when excited at 405 nm. On the other hand, degradation markers, like oxidation products and conjugated hydroperoxides, appear between 420–515 nm, signaling either quality decline or the presence of refined oils.

The front-face technique enhances fluorescence spectroscopy's practicality for olive oil. This method allows for the testing of undiluted, intact samples without requiring chemical solvents or extensive preparation, preserving the fluorophores' natural state. Adulterants also leave unique fluorescence patterns. For example, sunflower oil produces a broad peak around 469 nm due to conjugated hydroperoxides, while pure EVOO shows low-intensity doublet peaks in the same region. These distinct "fingerprints" help ensure precise quality assessments.

Benefits of Fluorescence for Olive Oil Testing

Fluorescence spectroscopy stands out for its ability to detect quality markers with high sensitivity. It can identify olive pomace oil adulteration in EVOO at concentrations as low as 3%. Laser-induced fluorescence (LIF) has demonstrated up to 93% sensitivity in spotting sunflower oil contamination. The technique requires minimal preparation and delivers fast results, making it ideal for quality control. In one study conducted by Hangzhou Dianzi University, a compact fluorescence sensor using a 395 nm UV LED achieved 100% accuracy in classifying olive oil into Extra Virgin, Virgin, and Lampante categories.

"The possibility of obtaining analytical signals in a nondestructive fashion, not altering the composition of the matrix, and measuring fluorophores in their native environment, is highly valuable for the quality control of olive oil samples." - Isabel Durán Merás, University of Extremadura

Another benefit is cost. LED-induced fluorescence systems are generally more affordable than laser-induced or mid-infrared alternatives operating in the UV spectrum.

Drawbacks of Fluorescence Technology

While fluorescence spectroscopy offers many advantages, it is sensitive to environmental factors like light exposure and temperature changes. These variables can introduce noise and compromise measurement accuracy. The technique may also struggle to detect adulterants with fluorescence characteristics closely resembling those of authentic EVOO. For example, in one comparative study, Excitation-Emission Matrix (EEM) fluorescence reached only 73% accuracy with certain algorithms, whereas methods like FTIR and Vis-NIR achieved 100% accuracy.

Additionally, interpreting fluorescence data often requires advanced chemometric tools like Principal Component Analysis (PCA) or Partial Least Squares (PLS) regression. Another challenge is the "inner filter effect", where a sample absorbs some of its own emitted light, complicating measurements.

NIR vs. Fluorescence: Side-by-Side Comparison

Detection Accuracy and Sensitivity

Both NIR spectroscopy and fluorescence spectroscopy excel in detecting adulteration, though they focus on different markers. NIR spectroscopy analyzes fatty acid profiles - such as linoleic and oleic acid levels - to identify refined oils or seed oil mixtures. On the other hand, fluorescence spectroscopy detects natural fluorophores like chlorophyll, tocopherols, and phenolic compounds. According to FDA data, over 60% of tested samples fail authenticity standards, highlighting the importance of these technologies.

Fluorescence spectroscopy shines in sensitivity, particularly for certain adulterants. Laser-induced fluorescence demonstrates 93% sensitivity for detecting sunflower oil and 88% for corn oil. Impressively, it can detect olive pomace oil contamination at concentrations as low as 3%, though it requires higher levels (15-16%) to reliably identify lower-grade olive oils.

By targeting distinct markers, these methods offer complementary strengths. Here’s a breakdown of their detection features:

| Detection Feature | NIR Spectroscopy | Fluorescence Spectroscopy |

|---|---|---|

| Primary Target | Fatty acid profiles and purity markers | Chlorophyll, tocopherols, phenolic compounds |

| Best For Detecting | Refined oils and seed oil mixtures | Pomace oil (3% threshold), oxidation products |

| Sunflower Oil Sensitivity | High for retail screening | 93% |

| Analysis Time | Less than 5 minutes | Seconds to minutes for rapid screening |

While detection accuracy is critical, practical considerations like cost, speed, and ease of use further set these methods apart.

Cost, Speed, and Ease of Use

Both technologies have become far more affordable in recent years. For instance, portable NIR devices, such as the Texas Instruments DLP NIRscan Nano EVM, cost around $999. Similarly, fluorescence systems benefit from low-cost LED excitation sources, making them equally accessible.

"Near-infrared spectroscopy (NIRS) technology... is a noninvasive, fast, or, if possible, real-time detection and affordable technique." - Candela Melendreras

Neither method requires sample preparation - no chemicals, no dilution, no damage to the oil. Both can analyze intact samples directly. NIR spectroscopy offers real-time results during extraction processes, while fluorescence spectroscopy (especially in front-face mode) provides rapid screening. Portable units with USB or wireless connectivity make these tools easy to use, even for non-experts.

The key difference lies in how the data is processed. NIR systems often come with preloaded calibration models, delivering straightforward results. Fluorescence spectroscopy, however, relies on chemometric analysis techniques like PCA or PLS regression, which require more expertise. For small-scale producers, portable NIR devices are ideal for their simplicity. Meanwhile, fluorescence spectroscopy is better suited for monitoring specific quality markers, such as chlorophyll degradation or oxidation, thanks to its exceptional sensitivity.

sbb-itb-4066b8e

Practical Uses for Olive Oil Producers

On-Site vs. Laboratory Testing

Deciding between on-site and laboratory testing comes down to your production workflow and quality control priorities. Tools like portable NIR and fluorescence sensors eliminate the need for costly lab setups and specialized operators, enabling real-time testing during critical stages like pressing or bottling.

In May 2021, researchers tested 27 olive oil samples and demonstrated that a miniaturized fluorescence sensor could achieve 100% classification accuracy across three quality grades - Extra Virgin Olive Oil (EVOO), Virgin Olive Oil, and Lampante Olive Oil - without requiring any sample preparation. Francesca Venturini, part of the research team, remarked:

"The results confirm that this minimalist low-cost sensor has the potential to substitute expensive and complex chemical analysis".

For producers like Big Horn Olive Oil, on-site testing ensures immediate verification of freshness and quality. Front-face fluorescence spectroscopy is particularly effective because it analyzes intact samples without dilution, avoiding any changes that might distort results. Similarly, portable NIR devices can identify specific adulterants, such as sunflower or flax oil, with determination coefficients exceeding 0.80.

That said, laboratory testing remains essential for legal certifications and meeting export requirements. NIR methods, for example, align with established standards like the AOCS Standard Procedure Cd 14f-14. Together, these testing methods allow producers to fine-tune their processes, regardless of production scale.

Small-Scale vs. Large-Scale Production

The scale of production also plays a significant role in choosing the right technology. Portable testing devices are particularly advantageous for small-scale producers. These devices are affordable, use simple LED excitation sources, and require no chemical expertise.

A 2023 study demonstrated the effectiveness of a portable NIR device in analyzing 96 olive oil samples adulterated with seed oils in concentrations ranging from 2% to 30%. Using Partial Least Squares regression, the portable prototype successfully quantified the adulterants, making it a practical on-site tool for non-specialist users. Ana Soldado from the University of Oviedo highlighted:

"Controlling impurity is a challenge involving authorities and the olive oil industry, requiring analytical alternatives based on real-time analysis that can be carried out onsite by non-expert personnel".

For large-scale producers managing high-volume operations, advanced tools like Hyperspectral Imaging (HSI) offer a robust solution for online quality control, providing both spatial and spectral data. NIR spectroscopy, which completes measurements in under 5 minutes, is especially useful for rapid screening during export preparation. For premium brands like Big Horn Olive Oil, combining on-site testing with lab certification ensures every bottle meets strict quality standards at every step - from harvest to retail - without disrupting production efficiency.

Exploring Fluorescence in Olive Oil with my Spectrometer

Conclusion: Which Method Should You Choose?

The choice of method depends on your production scale, budget, and specific quality control needs. NIR spectroscopy is perfect for high-volume producers, offering rapid screening (under 5 minutes) and a comprehensive fatty acid profile. Its speed and efficiency make it a go-to option for large-scale operations aiming to meet international trade standards. Plus, portable NIR units make this technology accessible for mid-sized producers as well.

On the other hand, fluorescence spectroscopy shines when it comes to detecting trace adulterants. It can identify contamination levels as low as 3%, focusing on markers like chlorophyll and phenolic compounds. This makes it a great choice for small-scale producers who need a simple, cost-effective, and non-destructive way to authenticate premium grades or monitor oxidation levels.

Key Takeaways

Both methods bring unique strengths to olive oil authentication, offering faster alternatives to traditional chromatography without sacrificing accuracy.

- NIR spectroscopy is ideal for monitoring multiple quality parameters at once, making it especially useful for managing diverse product lines and meeting export requirements.

- Fluorescence spectroscopy offers unmatched sensitivity for detecting specific adulterants and distinguishing Extra Virgin Olive Oil from lower-quality grades.

For producers aiming for Ultra Premium standards - like Big Horn Olive Oil - a combination of both methods can elevate quality control. Use NIR for quick batch screening during bottling and fluorescence for focused authentication of premium designations. Whether you prioritize speed and comprehensive analysis with NIR or precise detection with fluorescence, combining both ensures your olive oil meets the highest standards of excellence.

FAQs

How does near-infrared (NIR) spectroscopy detect adulteration in olive oil?

Near-infrared (NIR) spectroscopy helps uncover adulteration in olive oil by examining how the oil absorbs light at specific wavelengths. Each type of oil, like seed oils, has its own distinct absorption pattern, which NIR can detect.

With tools like multivariate analysis, NIR doesn't just identify adulteration - it can also measure the percentage of foreign substances mixed in. This ensures that olive oil meets quality standards, making NIR a dependable method for safeguarding authenticity.

Why is fluorescence spectroscopy so effective at detecting trace amounts of adulterants in olive oil?

Fluorescence spectroscopy is a powerful method for detecting trace adulterants in olive oil. It works by identifying specific compounds, like chlorophyll and phenolic compounds, which naturally emit light. These substances serve as reliable markers of purity, capable of uncovering even the smallest instances of adulteration.

Thanks to its precision, this technique plays a key role in verifying the authenticity of premium olive oils, including Ultra Premium Extra Virgin Olive Oils (EVOO). By pinpointing subtle chemical differences, it helps preserve the quality and trust that consumers associate with these high-grade products.

What is the most cost-effective spectroscopy method for small olive oil producers?

For small-scale olive oil producers, fluorescence spectroscopy stands out as a more budget-friendly option compared to near-infrared (NIR) spectroscopy. It’s simpler to use, relies on less expensive equipment, and requires minimal sample preparation - making it a practical choice for operations working with tighter budgets.

On the other hand, while NIR spectroscopy is known for its precision and fast analysis, it comes with a higher upfront cost due to the need for specialized sensors and calibration. For smaller producers, this might not be a feasible investment. Fluorescence spectroscopy provides an affordable and efficient way to detect adulteration and ensure quality control, all without sacrificing dependability.