Future of Olive Oil Certification Standards

The olive oil industry is grappling with trust issues due to widespread fraud. Between 2014 and 2024, over 200 cases of edible oil fraud were reported globally. With advanced methods being used to mimic real olive oil, traditional testing methods are struggling to keep up. Consumer demand for higher-quality olive oil, fueled by trends like the Mediterranean diet, has increased significantly, especially in the U.S., where consumption grew by 19% during the 2024/25 crop year.

Key Takeaways:

- Olive oil is one of the most adulterated food products globally.

- Fraudsters are using advanced techniques to bypass traditional testing.

- Certification standards, like those from the USDA and IOC, remain critical to ensuring quality but face challenges due to evolving fraud methods.

- New tools like blockchain, smart labels, and advanced chemical testing (e.g., NMR) are improving traceability and fraud detection.

- Sustainability is becoming a focus, with certifications now rewarding eco-friendly farming and production practices.

Major players like the Olive Oil Commission of California (OOCC) and the North American Olive Oil Association (NAOOA) are leading efforts to tighten standards, while companies like Big Horn Olive Oil are setting higher benchmarks through stricter quality controls.

Looking ahead, stricter global regulations, mandatory digital traceability, and advanced testing methods are expected to reshape the industry by 2030, addressing fraud and meeting consumer expectations for premium products.

Is your olive oil real or fake? How the Food Detectives can fight fraud using DNA tests

Current Certification Standards in the Olive Oil Industry

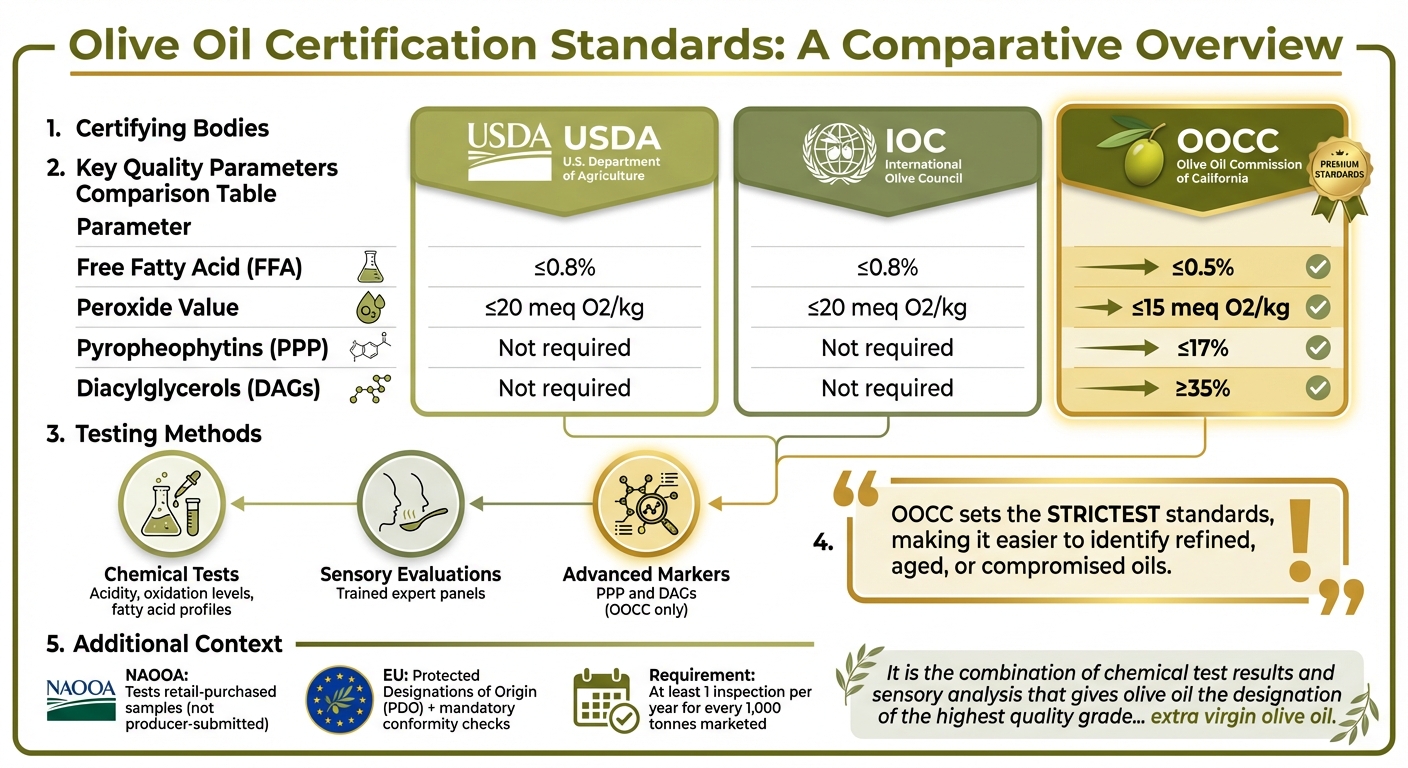

Olive Oil Certification Standards Comparison: USDA vs IOC vs OOCC Requirements

Global Standards: EU and US Certifications

Certifying olive oil involves a mix of chemical tests - like checking acidity and oxidation levels - and sensory evaluations carried out by trained experts. These methods help verify the oil's quality and authenticity. In the United States, three main organizations oversee these standards: the USDA (United States Department of Agriculture), the IOC (International Olive Council), and the OOCC (Olive Oil Commission of California).

The OOCC has particularly strict guidelines, setting lower thresholds for free fatty acids, peroxides, and other markers. This makes it easier to identify oils that are refined, aged, or otherwise compromised.

"It is the combination of chemical test results and sensory analysis that gives olive oil the designation of the highest quality grade... extra virgin olive oil." – California Olive Ranch

The North American Olive Oil Association (NAOOA) also plays a key role. Unlike many other certifiers, it tests retail-purchased samples rather than relying on producer-submitted products, ensuring a more accurate reflection of what consumers are buying. Over in the European Union, regulations include Protected Designations of Origin (PDO) and mandatory conformity checks, requiring at least one inspection per year for every 1,000 tonnes of olive oil marketed.

Despite these robust frameworks, ensuring authenticity remains a tough battle.

Challenges with Adulteration and Mislabeling

Fraud continues to plague the olive oil industry, even with advanced testing protocols in place. Adulteration techniques are constantly evolving, allowing fraudsters to mimic the fatty acid profiles of genuine olive oil. This means that testing methods must continually adapt to stay effective. Sensory evaluations, while critical, have their limitations too. In the EU, if a panel's findings are inconclusive, multiple reassessments are required, adding complexity to the process.

Cross-border enforcement is another hurdle. When irregularities are found in one country, but the producer operates in another, authorities must rely on administrative cooperation between nations - a process that can be slow and inconsistent. Testing every batch of olive oil is impractical, so authorities use a risk-based sampling approach, focusing on factors like price, blending practices, and origin. However, this method can miss smaller-scale or highly sophisticated fraud.

Conflicting standards between regions and organizations add to the confusion. Studies reveal widespread non-compliance with both state-specific and international guidelines. On top of that, consumer awareness is alarmingly low. Only 25% of U.S. olive oil users consider themselves "very or extremely knowledgeable" about the product, making them easy targets for misleading labels.

A notable example of industry intervention occurred in 2013 when the NAOOA sued Kangadis Food for falsely labeling its "Capatriti" brand as olive oil when it was actually pomace oil. A federal judge ordered the company to either recall or relabel the product, highlighting how trade groups can step in to address regulatory gaps.

New Trends in Certification Standards

Digital Traceability and Blockchain Technology

The olive oil industry is stepping up its game with digital tools aimed at tackling fraud and rebuilding consumer trust. Techniques like Nuclear Magnetic Resonance (NMR) and Mass Spectrometry (MS) are being used to create a unique molecular fingerprint for each oil. This chemical profile is stored in databases to verify the oil's geographical origin and detect any adulteration. These NMR-based models boast an impressive 98.5% accuracy rate in distinguishing oils from different regions, such as Italy and Tunisia.

Smart Labels are another innovation making waves. By linking lab test data directly to packaging, these labels let consumers scan a product to access harvest details, chemical analysis results, and authenticity certifications instantly. Producers are already using these tools, which are especially crucial for Protected Designation of Origin (PDO) products, where authenticity significantly impacts pricing.

Blockchain technology takes traceability even further. In October 2023, the Decapolis Company rolled out its Decapolis Food Guard (DFG) blockchain platform at an olive mill in Jordan. This system tracked every detail - from farmers to olive weight - while applying tamper-proof labels to containers. The mill owner reported a 15–25% sales boost, crediting blockchain validation for enhancing provenance and export opportunities. Blockchain creates secure, time-stamped records that can uncover complex fraud scenarios that traditional quality tests might miss.

In addition to traceability, certification standards are now prioritizing environmental aspects as well.

Sustainability and Environmental Certifications

Certification standards in the olive oil industry are evolving to reward sustainable farming methods alongside quality. For instance, Geographical Indications (GIs) - which traditionally focused on origin - now include regulations on irrigation limits, planting densities, and maximum yields to ensure long-term ecological balance. This is particularly crucial given that olive cultivation spans over 10 million hectares worldwide, with more than 90% in the Mediterranean region.

The International Olive Council (IOC) is also working on initiatives to certify olive groves as natural carbon sinks. Through its "Carbon Balance" project, the IOC aims to help farmers generate and sell carbon credits by adopting sustainable land management practices. This approach not only creates new revenue streams for eco-conscious producers but also addresses global climate concerns.

On a regional level, stricter quality parameters are being enforced with the help of newer technologies. For example, the Olive Oil Commission of California (OOCC) now mandates testing for Pyropheophytins (PPP) and Diacylglycerols (DAGs) - chemical markers that reveal heat damage, aging, and improper storage. These tests are considered the "gold standard" for ensuring freshness and shelf life. Additionally, the OOCC's Free Fatty Acid standard of ≤0.5% is more stringent than the ≤0.8% standard set by the USDA and IOC, reflecting a broader shift toward tighter quality controls.

sbb-itb-4066b8e

Predictions for Future Certification Standards (2026–2030)

Stricter Global Regulations and Enforcement

Over the next few years, voluntary certification processes will give way to mandatory digital oversight. In January 2026, Spain introduced a stricter framework under its National Official Control Plan (2026–2030). This plan mandates digital traceability tools, SIMO and REMOA, to monitor stock and bulk movements. At least 20% of operators will be audited annually to enhance control over both imports and domestic trade.

This shift from paper records to real-time digital monitoring is significant. Advanced traceability systems have already demonstrated their ability to cut compliance reporting errors by over 40%, making them a key tool in tackling issues like mislabeling. Simultaneously, the EU is modernizing its analytical methods under Regulation (EEC) 2568/91, replacing older testing protocols with faster, more efficient, and environmentally friendly alternatives. These updated methods use less solvent and deliver results more quickly.

"EU legislation, among the most advanced in the field, continuously chases after the emerging frauds." - JRC Publications Repository

In contrast, the United States has yet to establish a federal standard of identity for olive oil. However, a bipartisan bill introduced in 2026 aims to push the FDA toward creating such a standard, likely incorporating modern traceability measures. With global olive oil production for the 2025/26 season predicted to drop by 4% to 3.44 million tons, the need for stringent certification to combat price fraud becomes even more pressing.

These regulatory developments align with rising consumer expectations for products that are both verified and premium.

Growing Demand for Organic and Premium Products

As regulations tighten, the market is seeing a noticeable shift. Consumers are increasingly drawn to premium and organic olive oils, which is driving changes in certification standards. The organic edible oil market is projected to grow at an annual rate of 11.2% between 2025 and 2030, fueled by a preference for clean-label, verified products. Certification bodies are responding by integrating IoT tracking into organic and premium labels, ensuring transparency in claims about pesticide-free and sustainable production.

These stricter global regulations not only combat fraud but also improve market standards, boosting demand for high-quality products. AI-powered quality tests have become the norm for verifying authenticity. Cutting-edge technologies like high-resolution mass spectrometry, paired with data analysis methods such as PCA and PLS-DA, are now used to identify reliable biomarkers like stigmastadienes and sterolic profiles. These advancements are slashing lab testing times while maintaining accuracy.

"Technological innovations such as AI-driven quality assessment and IoT-enabled supply chain traceability enhance product authenticity and operational efficiency." - Market Size and Trends

Producers are also adopting transparency-focused strategies, such as QR codes and blockchain-enabled packaging, to build trust with consumers across both online and offline channels. Early adoption of these tools will better position brands to comply with the stricter National Official Control Plans expected across major EU olive oil–producing nations by 2030.

The Role of Big Horn Olive Oil in Setting Quality Standards

Big Horn Olive Oil has positioned itself as a leader in raising the bar for olive oil quality by adhering to Ultra Premium standards that go beyond USDA and IOC requirements. By aligning with the rigorous guidelines of the Olive Oil Commission of California (OOCC), the company ensures Free Fatty Acid (FFA) levels remain at or below 0.5%. This is a step above the USDA and IOC allowance of 0.8%, signifying the use of higher-quality olives during milling.

Freshness is at the heart of Big Horn Olive Oil's process. The olives are cold-pressed within two hours of harvest, preventing sensory defects caused by delays. Advanced chemical tests are then conducted to confirm the oil's freshness, ensuring PPP levels are ≤17% and 1,2-DAG values are ≥35%. These precise tests are paired with thorough sensory evaluations to uphold quality.

"It is the combination of chemical test results and sensory analysis that gives olive oil the designation of the highest quality grade of olive oil, extra virgin olive oil." - California Olive Ranch

The company guarantees Extra Virgin certification by conducting both chemical and sensory testing, meeting the highest industry standards.

Big Horn Olive Oil's commitment to quality extends to its sourcing practices. Its balsamic vinegars are procured exclusively from Modena, Italy, ensuring authenticity and adherence to traditional aging methods. Additionally, the company maintains Peroxide Values at ≤15 meq O2/kg, surpassing the standard ≤20 meq O2/kg, further solidifying its dedication to premium-quality products.

Conclusion

Olive oil certification depends on stricter regulations, advanced testing methods, and building trust with consumers. Fraud continues to challenge the industry, making it essential to refine standards that protect both producers and buyers. Efforts are already underway, with EU authorities employing risk-based conformity checks. These checks focus on high-risk operators and prioritize inspections based on factors like past violations and product volume.

Looking ahead to 2030, certification processes are expected to integrate precise chemical markers such as Pyropheophytins (PPP) and Diacylglycerols (DAGs) alongside traditional sensory evaluations. These advancements will help verify freshness and authentic flavor profiles. As noted by the JRC Publications Repository, "The process of proposing new methods or reviewing those current is constantly in progress, to ensure the robustness and the clarity required by official standardised procedures". Such updates will push the industry toward greater accountability.

Maintaining market integrity hinges on proactive regulation and a collective commitment to quality. Tools like smart labels, blockchain-based traceability, and stronger enforcement measures will help close existing gaps in legislation. Outdated tests need to be replaced with modern, efficient analyses. Companies that go beyond the minimum requirements - like those adhering to the Olive Oil Commission of California's stricter standards - set a strong example for fostering consumer trust and establishing global benchmarks. Collaboration among producers, regulators, and certification bodies is essential to ensure every bottle lives up to its promise of authenticity.

These developments highlight the importance of leadership in advancing quality standards. Companies such as Big Horn Olive Oil demonstrate this by ensuring every bottle of their Ultra Premium Extra Virgin Olive Oil meets the most rigorous authenticity criteria.

FAQs

How does blockchain technology help ensure the authenticity of olive oil?

Blockchain technology is transforming how we verify the quality and origin of olive oil. By creating a secure digital record of the oil's journey - from the grove where olives are harvested to the bottle on the shelf - it ensures every step of the supply chain is documented. This means the product’s origin, quality, and purity are safeguarded against tampering.

For consumers, accessing this information is straightforward. Tools like QR codes or RFID tags on the packaging allow you to view verified details about the production process and quality testing. This transparency not only builds trust but also guarantees you're purchasing olive oil that meets the highest standards.

What makes detecting olive oil fraud so challenging?

Detecting fraud in olive oil is no easy task. The product's complexity and the increasingly clever ways fraudsters tamper with it make this a tough nut to crack. Common schemes include blending high-quality extra virgin olive oil with cheaper oils or misrepresenting its origin and grade. These deceptions are often subtle, making them hard to catch with simple tests.

Adding to the challenge is olive oil's natural variability. Factors like the type of olive, when it’s harvested, and how it’s processed can all influence the oil’s characteristics. This makes distinguishing genuine olive oil from adulterated versions even trickier. To combat this, experts rely on advanced tools like spectroscopy, chromatography, and DNA analysis. While effective, these methods come with downsides - they’re expensive, time-consuming, and demand specialized knowledge.

With fraudsters staying one step ahead and testing requiring significant resources, ensuring consumers get authentic, high-quality olive oil remains an ongoing battle for the industry.

Why do we need stricter global standards for certifying olive oil?

Stricter global standards for olive oil certification play a key role in guaranteeing that consumers get genuine, high-quality products. These regulations address problems like mislabeling, adulteration, and fraud - issues that can deceive buyers and tarnish the industry's reputation.

When consistent rules are enforced across the globe, producers are required to meet higher quality standards. This benefits consumers by ensuring they can trust what they're purchasing, while also safeguarding the credibility of premium olive oil brands that emphasize transparency, freshness, and superior quality in their products.