Roundup of Projects Using Olive By-Products for Bioplastics

The olive oil industry produces vast amounts of waste - like pomace, pits, and leaves - that are often discarded. But now, these by-products are being turned into bioplastics, offering a natural alternative to petroleum-based plastics, which take centuries to decompose. Bioplastics made from olive waste can break down in about a year, making them a practical solution for reducing plastic pollution. Plus, this shift creates new income opportunities for farmers and rural communities.

Key projects include:

- OLinWASTE: A zero-emission biorefinery converting olive mill waste into bioplastics, biofertilizers, and energy.

- E-OilÉ: Developing food-safe, compostable packaging from olive residues.

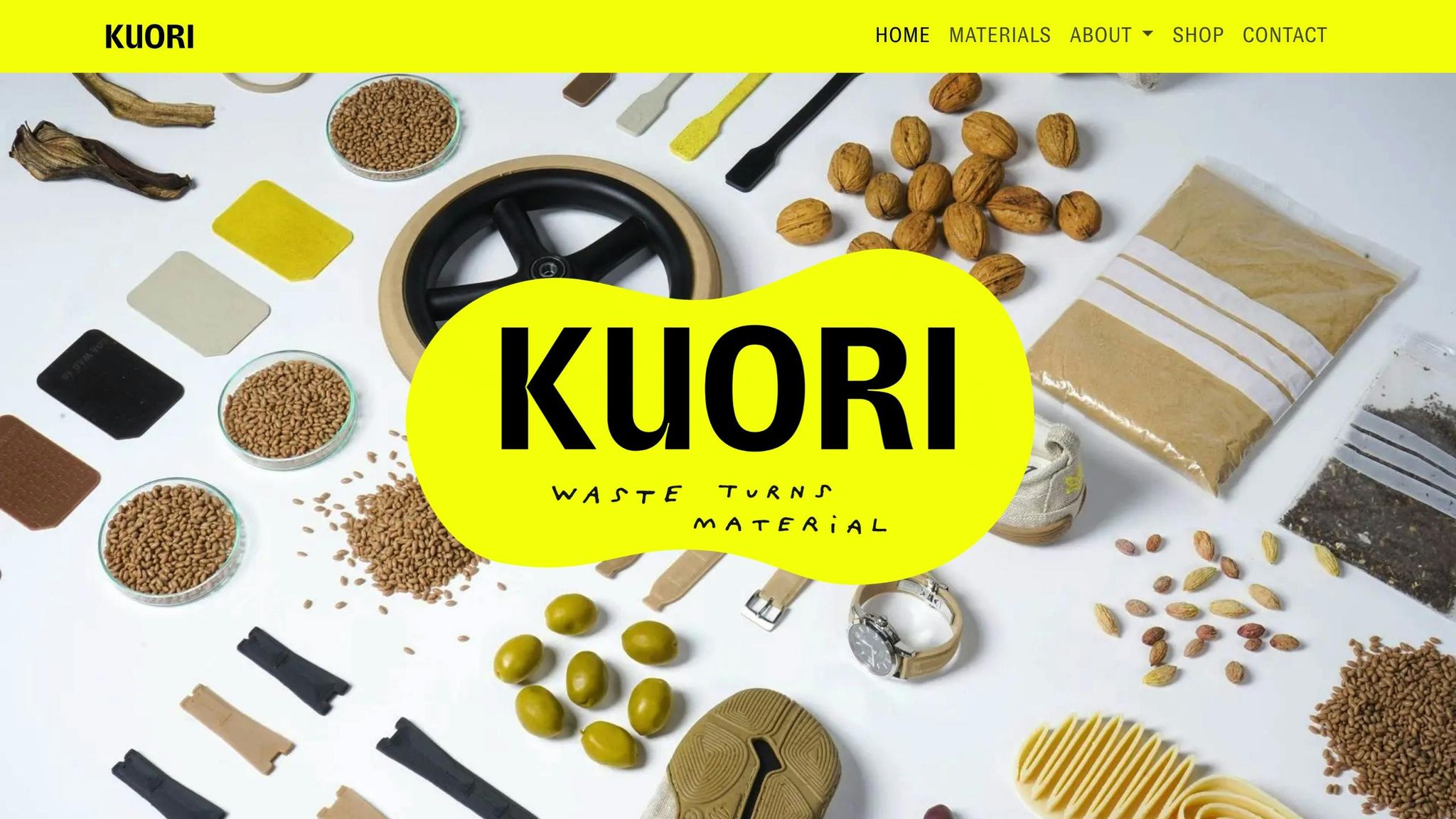

- Kuori: Transforming olive pits into biodegradable thermoplastics.

These initiatives highlight ways to turn agricultural waste into useful, eco-friendly materials, while also addressing challenges like food safety regulations, seasonal feedstock availability, and cost competitiveness.

Projects Converting Olive By-Products into Bioplastics

OLinWASTE: Zero-Emission Biorefinery for Olive Waste

The OLinWASTE project, spanning four years and funded with nearly €4 million ($4.2 million) from Horizon Europe, brings together nine European partners to create a zero-emission biorefinery. Led by the University of Surrey, the initiative uses a digital twin to fine-tune operations before scaling up the physical infrastructure.

This project transforms olive mill waste - such as pomace, stones, and leaves - into a variety of products, including bioplastics for packaging and agricultural films, biofertilizers, biopesticides, plant bio-immunostimulants, and bioenergy through anaerobic digestion. By employing green chemistry and microbial fermentation, OLinWASTE extracts valuable components while minimizing emissions.

E-OilÉ: Food-Grade Packaging from Olive Residues

Based in Spain, the E-OilÉ project focuses on creating biodegradable, food-safe packaging from olive pomace. The process begins with traceable feedstock that is carefully washed, de-oiled, and thermally treated to eliminate contaminants.

The resulting materials are blended with biodegradable polymers like PLA or PBAT and tested under EU Regulation (EC) No 1935/2004 to ensure food safety. These materials are designed to match the mechanical, barrier, and thermal qualities of traditional plastics, while also breaking down cleanly in composting environments.

Kuori: Thermoplastic Materials from Olive Pits

Kuori is investigating how olive pits can be converted into biodegradable thermoplastic granules. Although details about the processing techniques and applications are still unfolding, the project shows promise in repurposing this unique by-product into sustainable materials. Early testing suggests strong mechanical properties, but further research is needed to refine the methods. Together, these initiatives highlight innovative ways to turn olive by-products into eco-friendly bioplastics.

Material Insight: Bioplastic Made from Olive Pits

Technologies for Converting Olive Waste into Bioplastics

Recent advancements have made it possible to transform olive by-products into bioplastics and other valuable materials, supporting a circular economy that reduces waste and maximizes resource use.

Biodegradable Polyesters from Olive Oils

Olive oil and its fatty acid derivatives can be chemically modified and processed through polycondensation to create biodegradable polyester chains. These chains are often blended with materials like PLA, PHA, or starch to improve flexibility, water resistance, and barrier properties. The result is a material well-suited for food packaging and other consumer products, offering a practical combination of strength, flexibility, and controlled degradation.

While these chemical processes produce flexible polymers, olive by-products also contribute to bioplastics as natural reinforcements.

Olive Pits and Pomace as Bio-Fillers

In addition to chemical transformations, olive pits and pomace are used to strengthen bioplastics naturally. The lignocellulosic structure of olive tree biomass contains 30–40% cellulose, making it an affordable and effective reinforcement material. Pruning residues, such as leaves and branches, can be processed to extract cellulose, which is then acetylated to produce cellulose acetate. This transparent biopolymer is known for its excellent thermal stability.

Studies by researchers at the University of Jaén and the Andaltec Foundation have shown that cellulose acetate derived from olive pruning waste can withstand temperatures ranging from 572°F to 752°F (300°C to 400°C). This makes it suitable for applications like food-packaging films and industrial components requiring heat resistance. Additionally, these materials are compatible with conventional extrusion and injection-molding equipment, offering a practical option for manufacturers in the U.S. seeking sustainable alternatives.

Beyond individual components, integrated systems are designed to maximize the potential of olive waste.

Integrated Biorefinery Systems for Multiple Products

Integrated biorefinery systems treat olive mill waste - such as pomace, stones, leaves, and wastewater - as a unified feedstock that can be processed into multiple products. These systems produce bioplastics, biofertilizers, biopesticides, plant bio-immunostimulants, and bioenergy.

Processes like solid-liquid separation, extraction, fermentation, and anaerobic digestion are used to generate bioplastic precursors, biogas, and nutrient-rich biofertilizers. Bioactive compounds extracted during this process can be formulated into biopesticides or plant stimulants. This cascading approach creates a circular model where bioplastics are one of several high-value outputs, alongside energy and agricultural products that can be reintegrated into olive-growing regions.

sbb-itb-4066b8e

Comparison of Olive Waste Bioplastics Projects

Comparison of Three Olive Waste Bioplastics Projects: OLinWASTE, E-OilÉ, and Kuori

Project Comparison Table

The three highlighted projects take unique paths in transforming olive by-products into bioplastics, utilizing various feedstocks, producing different outputs, and operating at distinct development stages.

| Project | Main Feedstock | Primary Products | Development Stage | Key Environmental Benefit |

|---|---|---|---|---|

| OLinWASTE | Olive mill waste (pomace, stones, leaves) | Bioplastics, biofertilizers, biopesticides, plant biostimulants, bioenergy | EU pilot/demonstration (TRL 5–7); ~$4.2 million funding over 4 years, starting June 2025 | Zero-emission integrated biorefinery; multiple value streams from the same waste |

| E-OilÉ | Olive oil production residues | Food-grade compostable packaging (films, trays, coatings) | EU collaborative project (TRL 5–7); targeting food-contact applications | Circular packaging from the same agricultural chain; biodegradable and compostable |

| Kuori | Olive pits | Thermoplastic materials for consumer goods and packaging | Startup commercialization (TRL 7–9); niche applications | Breaks down in ~1 year compared to ~450 years for traditional plastics |

These projects cater to different market demands while advancing the circular economy in olive production.

Production and Regulatory Challenges

While these projects bring innovative solutions, they face shared production and regulatory obstacles. For instance, food-contact safety is a significant concern for E-OilÉ and similar packaging applications. Materials must pass migration testing under FDA standards in the U.S. to ensure they don’t transfer harmful substances to food. Additionally, achieving compostability certification - whether ASTM D6400 (U.S.) or EN 13432 (EU) - requires clear labeling to inform consumers if the materials need industrial composting facilities or can break down in home compost setups.

Feedstock logistics also pose a challenge. Since olives are harvested seasonally, manufacturers need to either stockpile raw materials or develop preservation techniques to maintain feedstock quality for year-round production. On top of this, the cost gap between olive-based bioplastics and traditional petroleum-based plastics remains a barrier. To compete, manufacturers must either target eco-conscious consumers willing to pay a premium or refine production processes to lower costs.

Performance requirements vary by application. For food packaging, materials need to provide effective barriers against moisture and oxygen, sufficient mechanical strength for handling, and thermal stability during processing at temperatures ranging from 572°F to 752°F (300°C to 400°C). Striking the right balance is essential - materials that degrade too quickly might fail to protect products during their shelf life, while those that take too long to break down lose their environmental edge.

Conclusion

The idea of turning olive by-products from waste into resources like bioplastics, bioenergy, and biofertilizers is reshaping the olive oil industry. Initiatives such as OLinWASTE highlight how integrated biorefineries can convert olive waste into a variety of useful products. Meanwhile, research has shown that olive pruning can produce food-grade cellulose acetate, meeting high thermal and processing standards. These developments bring practical advancements to both production efficiency and sustainability.

For premium producers like Big Horn Olive Oil, these innovations open doors to pilot projects in secondary packaging - such as creating eco-friendly boxes, labels, and inserts - before expanding into food-contact applications. By working together with nearby growers or mills to collect residues, what was once waste can now be turned into valuable resources.

Additionally, implementing tracking systems for by-product diversion not only strengthens sustainability certifications but also adds depth to consumer narratives, enhancing the perception of quality and environmental responsibility.

In the short term, the focus can be on testing olive-waste materials for non-food-contact uses. As food-grade options become more widely certified, producers can scale up, aligning these breakthroughs with high-quality standards and the goals of a circular economy.

FAQs

What makes olive by-products a good alternative for bioplastics compared to traditional materials?

Olive by-products offer a biodegradable and environmentally conscious alternative for creating bioplastics. By transforming waste from olive processing into useful materials, they cut down dependence on petroleum-based plastics and lessen the strain on the environment. This approach not only reduces waste but also boosts the olive industry by converting leftovers into a resource with practical value.

What challenges come with turning olive by-products into bioplastics?

Using olive by-products to develop bioplastics isn't without its hurdles. One major challenge lies in the variability of olive waste composition, which can make it tough to maintain consistent quality in the final product. On top of that, extracting usable materials often comes with a hefty price tag and demands significant resources. There are also environmental concerns to consider, especially when chemicals are involved in the processing or when dealing with leftover waste. Even with these obstacles, advancements in technology and processes are steadily working to tackle these issues, paving the way for olive by-products to play a role in more sustainable materials.

How do projects like OLinWASTE and E-OilÉ maintain food safety in their bioplastic products?

Projects such as OLinWASTE and E-OilÉ place a strong emphasis on food safety by enforcing strict quality control practices and following established food safety guidelines. They meticulously test their bioplastic products at every step of the production process to ensure they remain uncontaminated and safe for use.

These efforts center on upholding cleanliness, identifying potential hazards, and utilizing advanced testing methods. The goal? To produce materials that are not only reliable but also meet the high standards expected by both consumers and regulators.